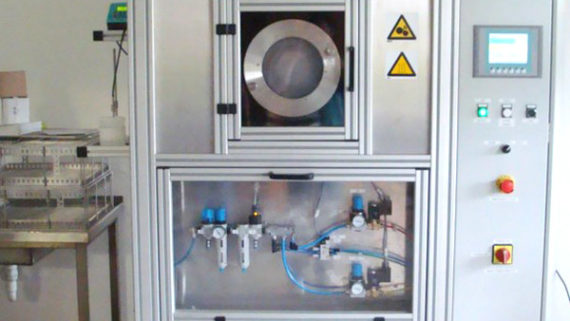

BURE - Machine for cleaning of fire grids

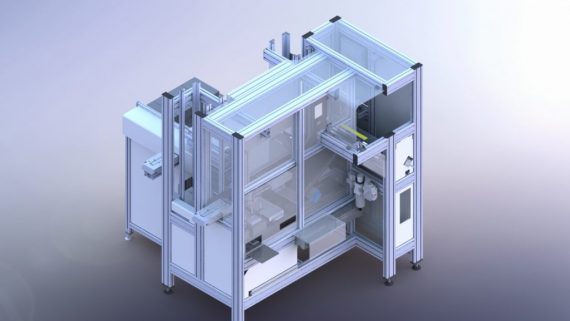

The machine is designed for cleaning grids, where after baking pieces, comes to sticking pieces to sieves (clay). Removing pieces from grids is made by brushes.

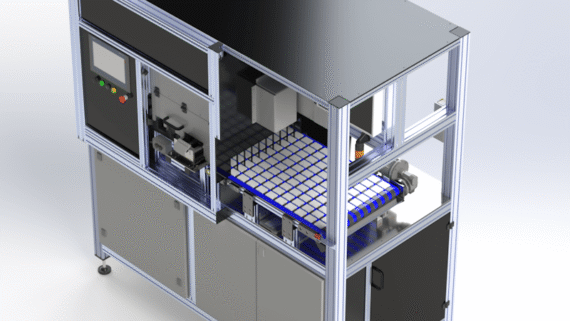

Machine operation is derived in several phases:

• Input container sieves

• The system accepts and transportation sieves

• The system of rotating brushes

• Output container sieves

• Positioning System brushes

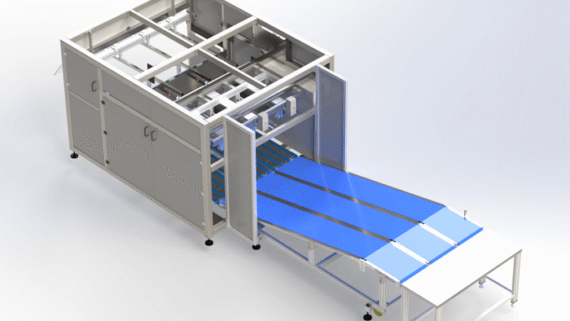

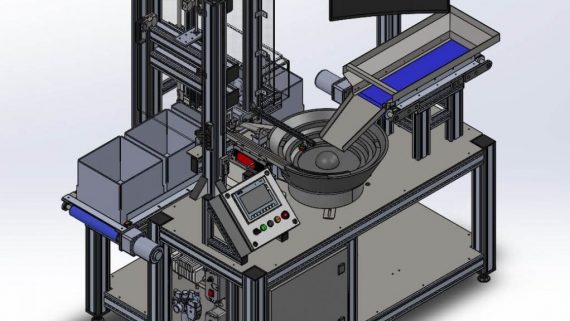

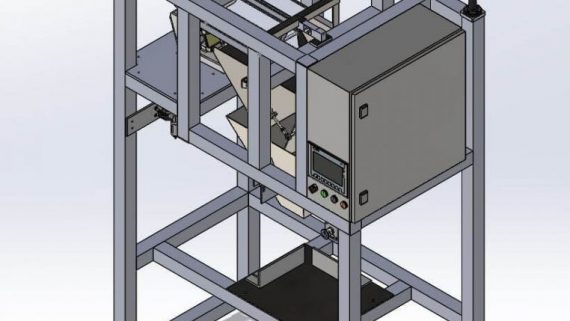

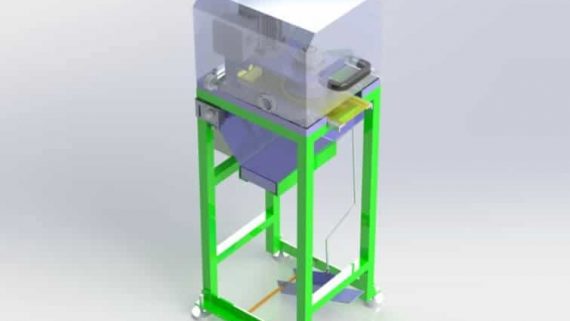

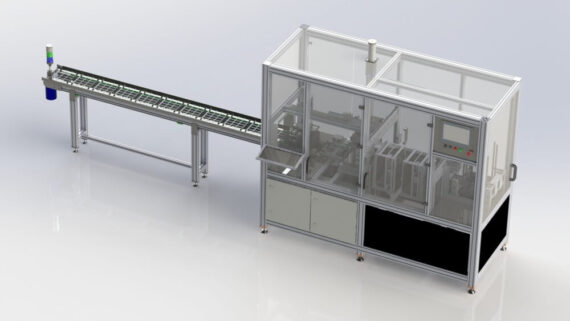

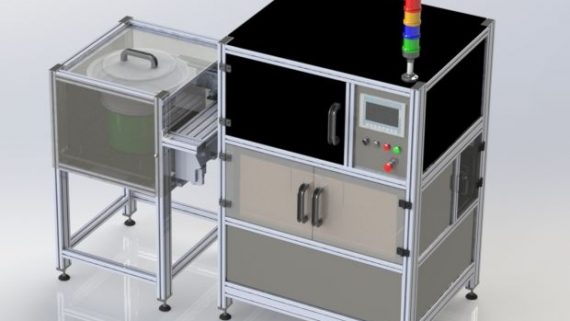

Input sieves container allows the operator to easily set uncleaned sieves in the input container. It consists of rails which direct the sieves to pneumatic cylinders and lifting table, which transfers sieve to system acceptance and transport.

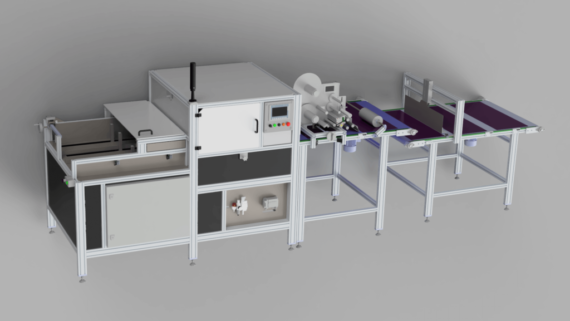

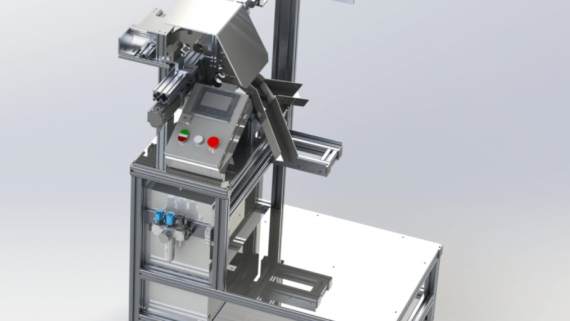

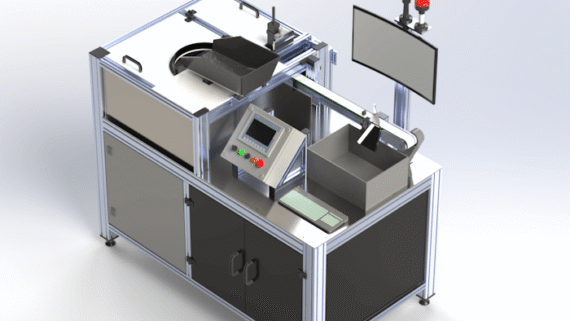

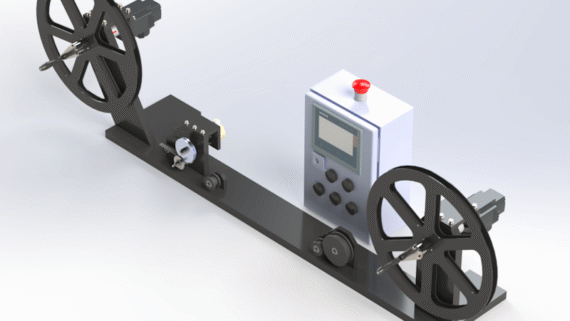

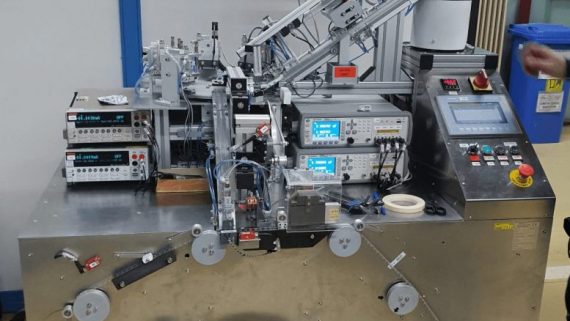

The transport system consists of two linear axes connected with solid shaft and driven by stepper motor. On linear axes there are clamps that hold the sieve in place. One gripper is passive, while the other is driven by pneumatic cylinder.

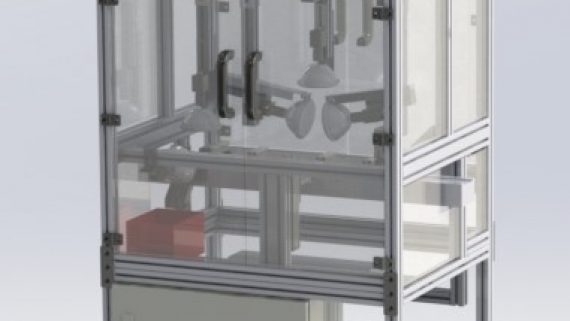

After the sieve is placed in the grippers, linear axes transport sieve within the system of rotating brushes, where the sieve is cleaned of glued pieces. This kind of system consists of two rotating brushes, AC motor and vacuum cleaner intake.

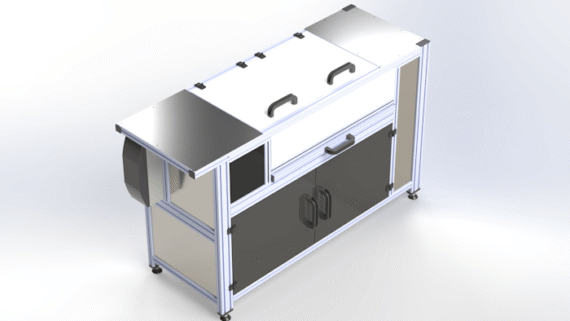

After passing between brushes, cleaned sieve comes to system output container, which consists of the lifting cylinder, the cylinder for release grips and levers to hold sieves in the output container.

Brushes positioning system consists of threaded spindle for vertical positioning. Brush height is changed manually. Brush height is adjusted according to the position of passing sieves between brushes.

Video of working machine is avalaible on our youtube channel : BURE