Bowl, linear, step, incline feeders, separators, vibro hoppers,

Presentation

Feeding system

A feeding system in the production process serves to dose bulk materials or to extract, position and guide them into a series of production parts to manipulate them in the desired manner. It consists of a input basket where bulk material or production pieces are filled. At the output of the feeding system the material is dosed or the parts come out stacked in the row.

The most important features of the feeder system are autonomy duration and capacity (feed rate).

Vibro and step feeders

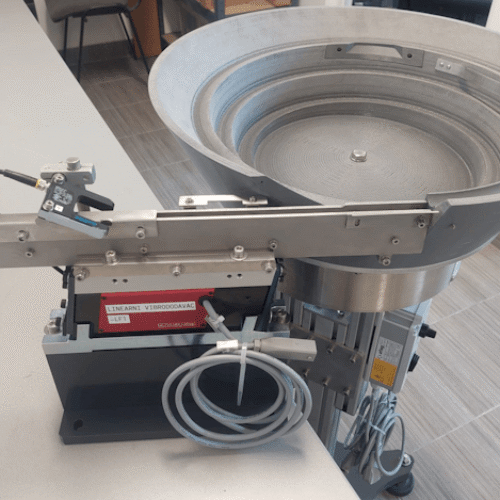

Vibratory feeders – consists of a drive and a guide section. The actuator is a vibrator that has its own control unit for the vibrations that are transmitted to the guides. The guide segment may be a bowl (circular guide) or a guide (linear guide).

The bowl has its own volume that is designed for a number of pieces. The trails in the bowl serve to separate, orient and guide the pieces in a row.

The guide can be made as a channel for transporting the material or as a buffer for the parts.

Step feeders – consists of a input basket and extraction plates. The input basket has a volume that is designed for a certain number of parts. The plates are moved to separate the parts into a row on the last plate for further processing.

Appliance

Bowl vibratory feeders: orientation of various production parts and stacking (contacts for switches, chips, plastic covers, screws …)

Linear vibratory feeders: at the outlet of bowl feeder, they serve as a part buffer for acceptance to an another process (taking a parts by robotic arm, releasing a series of parts for optical processing …) or as dosing of materials (dosing a certain mass or volume for product packaging, constant material dosing to the production line).

Step feeders: extract various production parts such as rollers, screws, pins, nuts. It is most commonly found in combination with a conveyor belt or a linear vibrator for further processing.

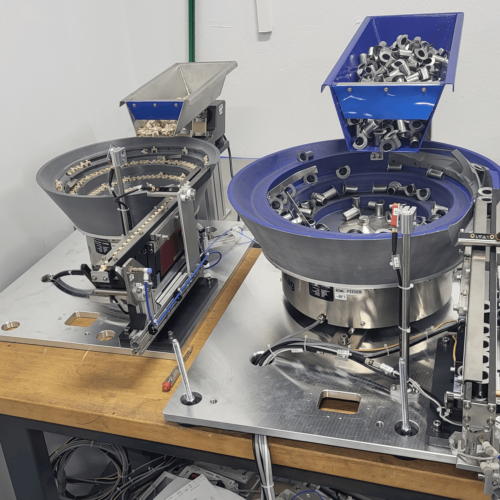

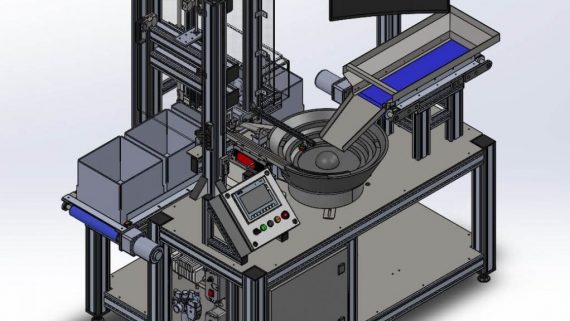

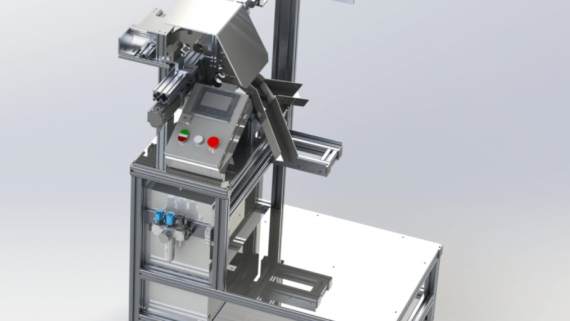

Vibro feeding system

The system consists of two vibrator feeders. The bowl on the first vibrator is used to orient and line up the parts. The guide on the second vibrator serves as a buffer for the parts from the first feeder. At the end of the linear feeder is an acceptance for further processing.

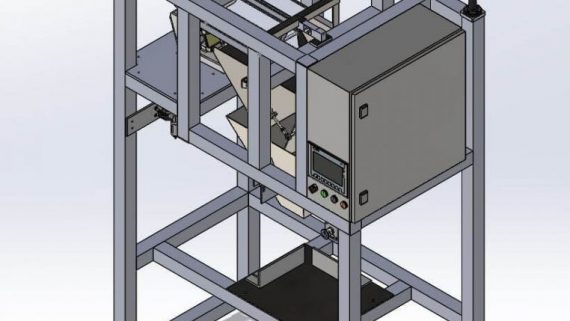

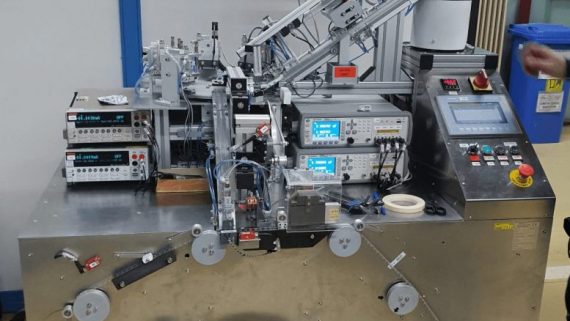

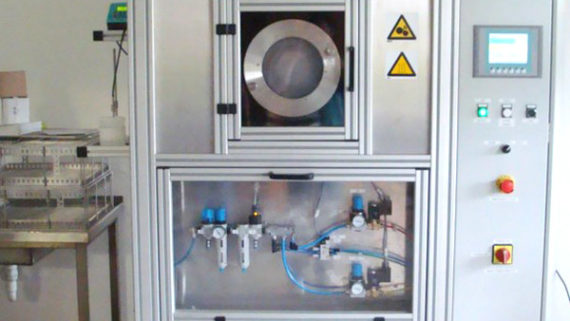

Step feeder

The system consists of a step feeder and a linear feeder. The step feeder extract the parts from the basket and places them on the conveyor belt for further processing.

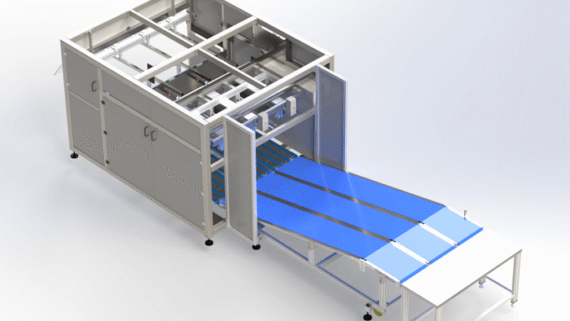

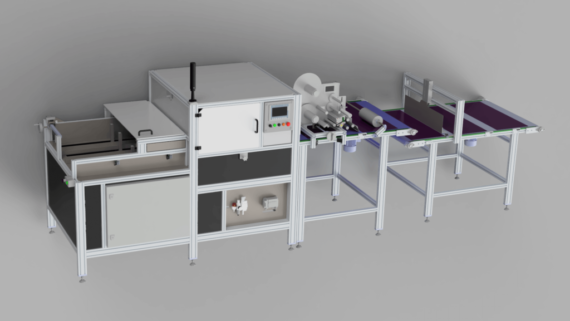

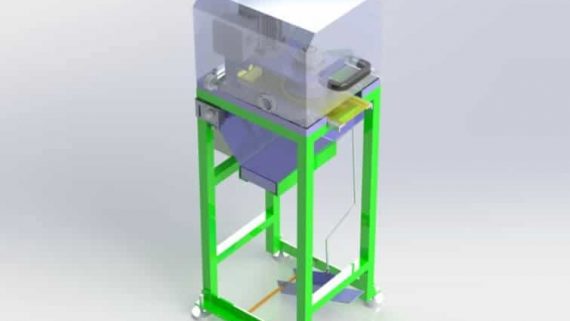

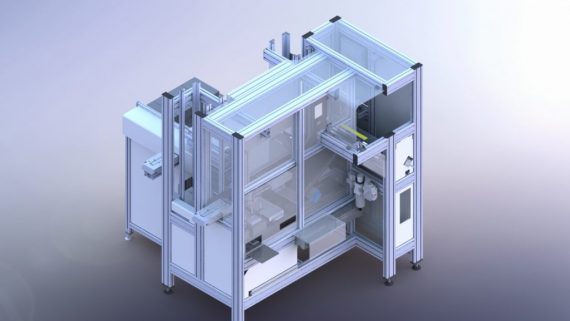

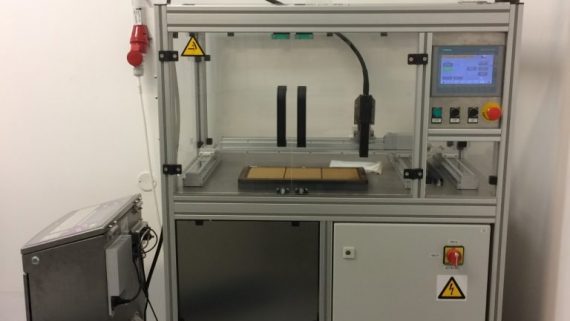

Universal disperser

The system is intended for processes where the production piece is frequently changed. The pieces are scattered on the plate, while at the other end of the plate a robot with an optical system recognizes and picks up the pieces. There is no need to physically adjust the feeder.

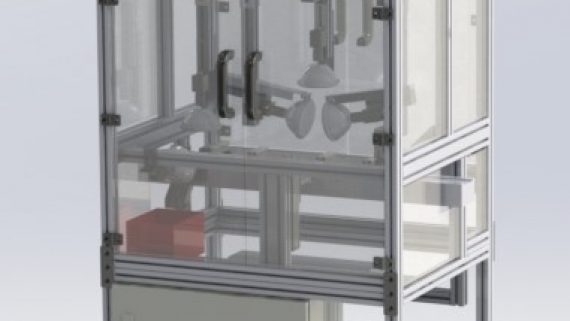

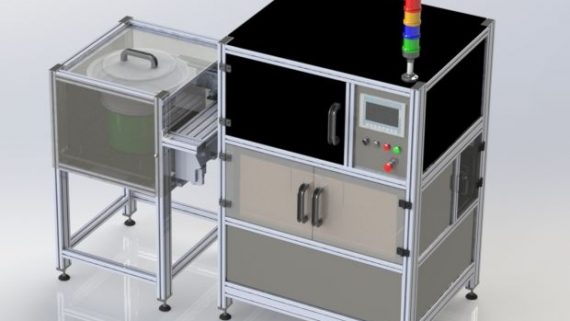

Bowl feeder for washers

Bowl feeder is 3D printed. Linear vibro feeder is made of INOX. State-of-the-art German equipment is used for propulsion. The feeder can be set to operate multiple types of washers. Feeder capacity is over 60 pcs per min. Autonomy depends on the depth of the basket, which is custom made.

Delivered feeders gallery

Videos of other feeders and machines can be viewed on our Youtube channel.