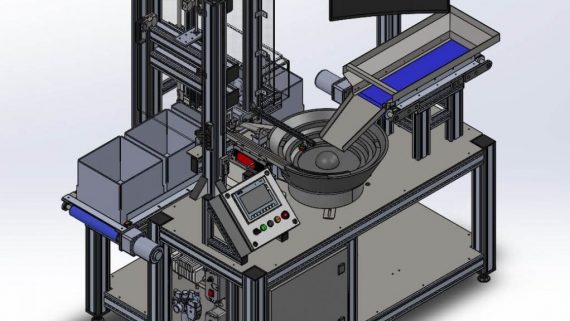

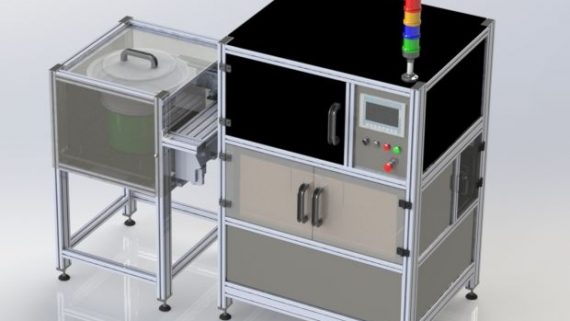

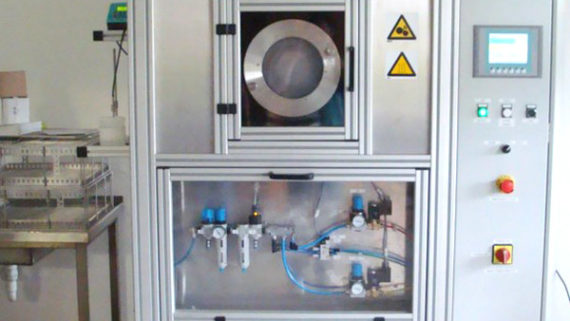

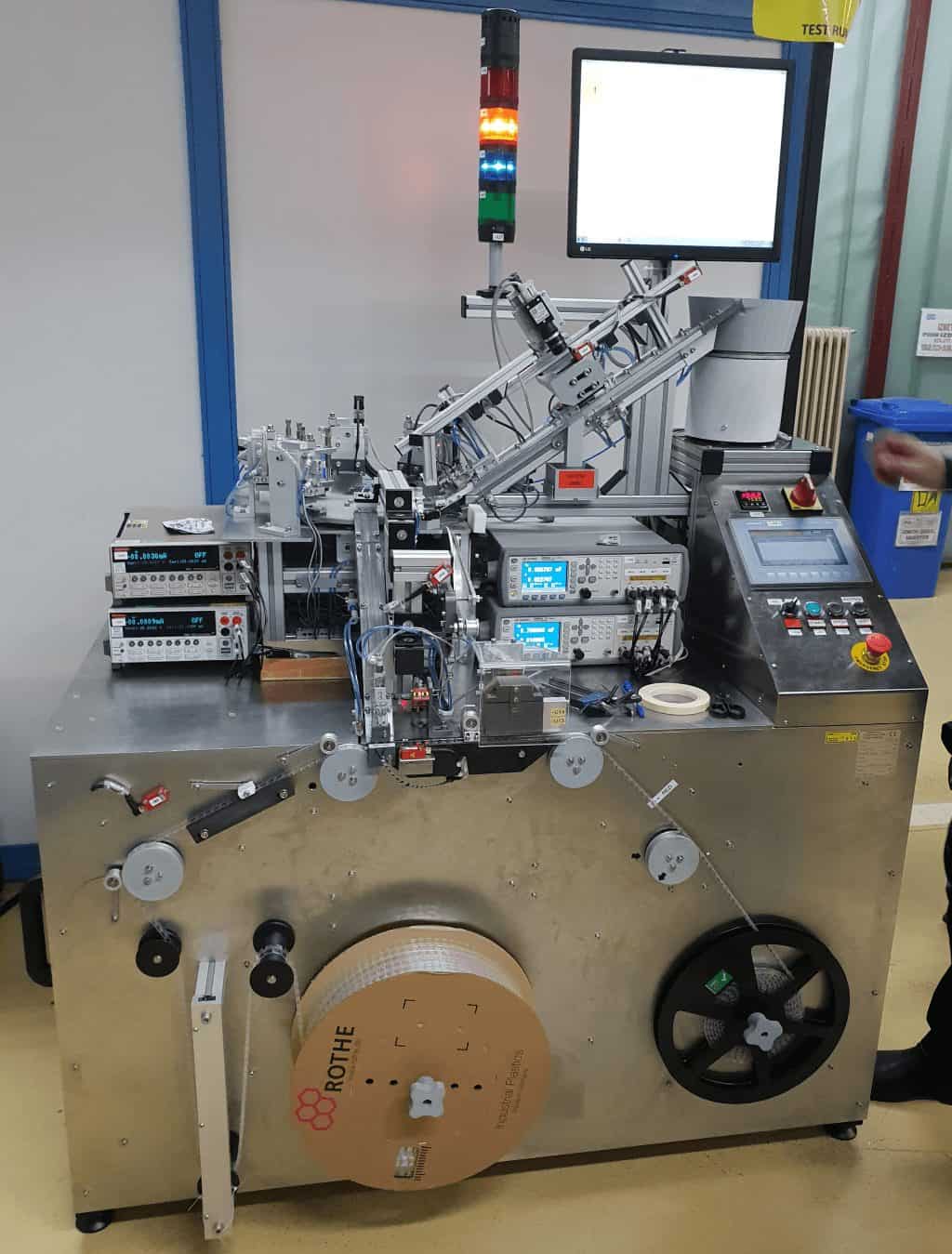

KOMPA - PS01 - Machine for orienting, optical and electrical measuring and packaging of electronic components

KOMPA is a machine for orienting, optical and electrical measuring and packaging of electronic components. The final product is full carrier tape with sorted and processed electronic components..

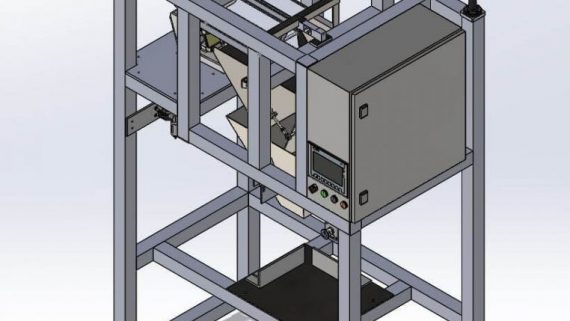

1. Control – Operations are performed automatically by the PLC controlling program. Actuators are servo drives and pneumatic cylinders.

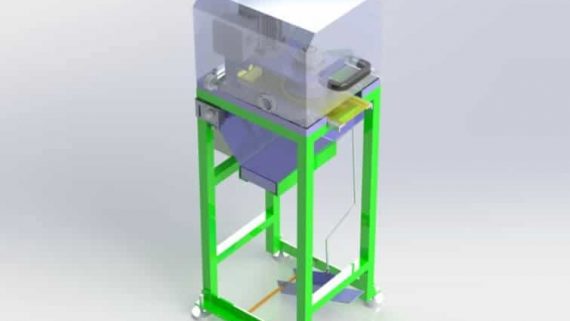

2. Input – Operator puts parts in bowl feeder. At the outlet of the bowl feeder the parts are oriented properly.

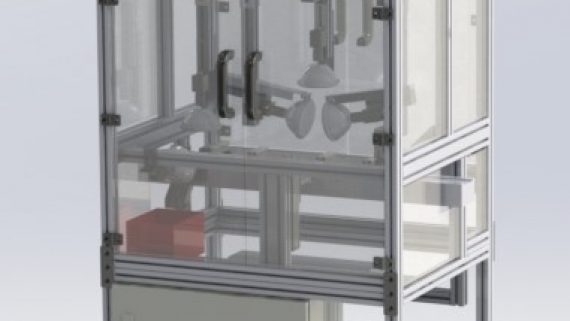

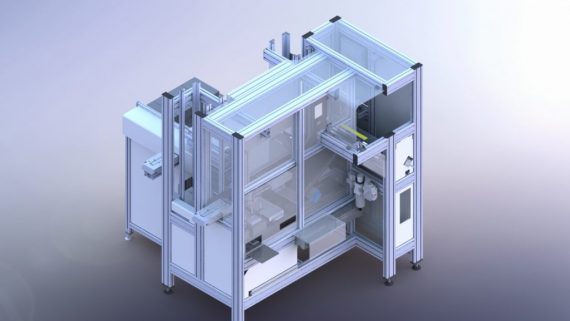

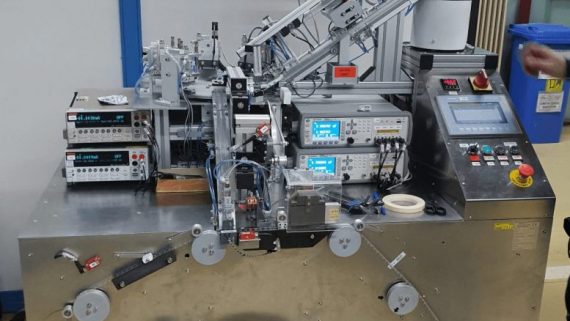

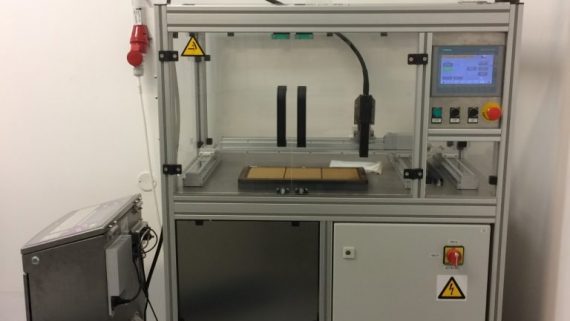

3. Optical measurement system – Components come on the optical control with camera to measure the dimensions of the parts.

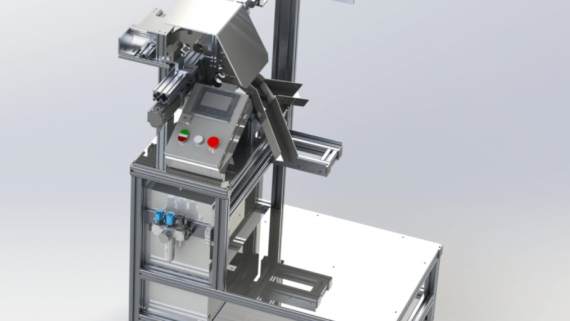

4. Electrical measurement system – Optically good components come on the rotary table for electrical measurement.

5. Marking system – Electrically good components are marked.

6. Filling the carrier tape – Marked parts fill the carrier tape. Tape is moves depending on the number of parts in the nest on the table. Heater welds the cover the carrier tape.

The other machines can be seen on our youtube channel.