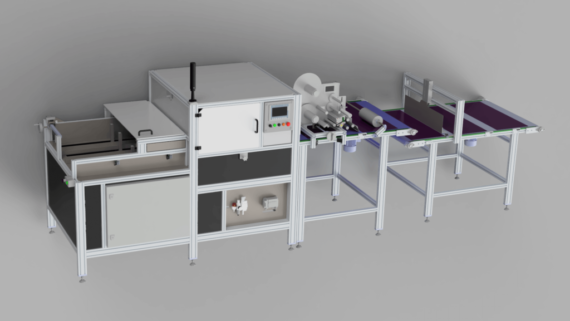

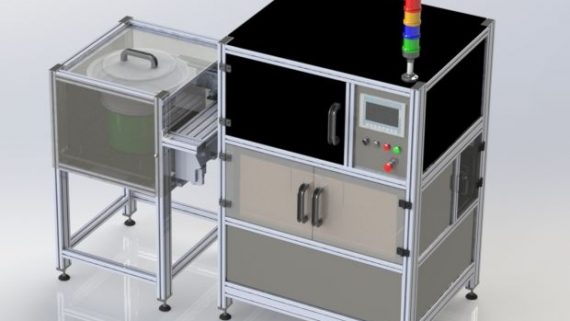

PLOK - PS01 - Machine for orienting, optical control and packing plastic parts

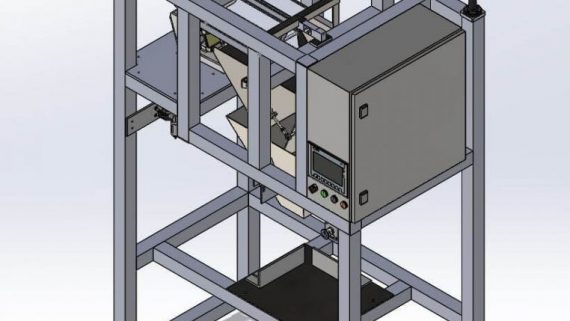

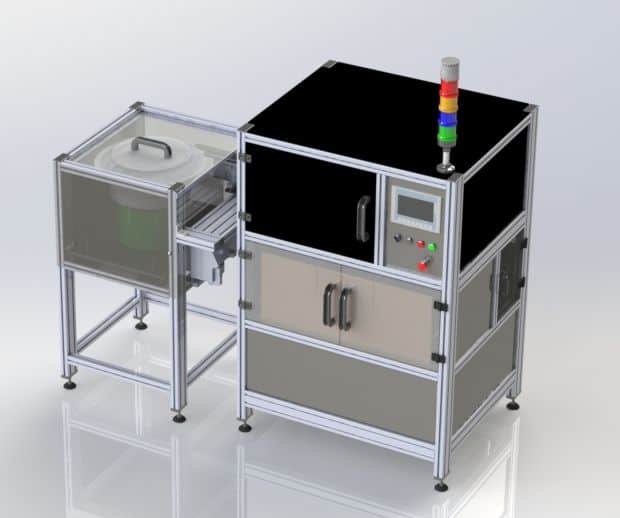

“PLOK – PS01” is a machine for orienting, optical control and packing plastic parts. Final product is a full box of OK parts.

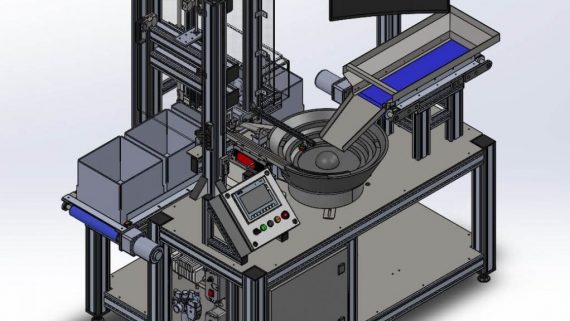

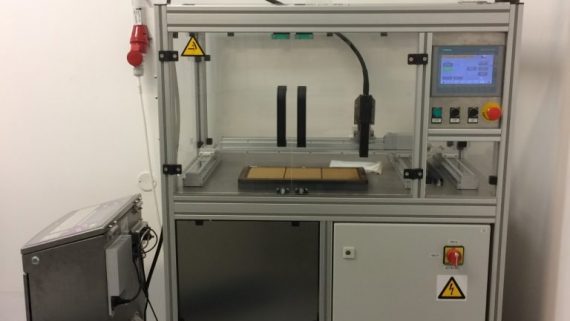

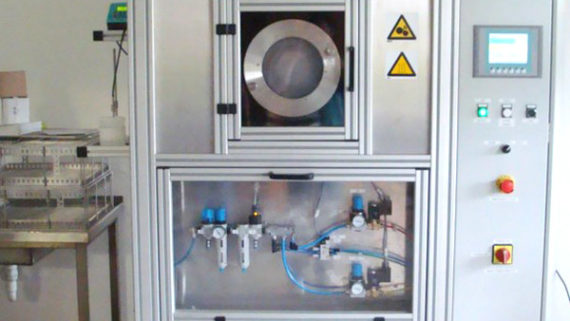

Actuators: rotary table, pneumatic cylinders, vibro feeders.

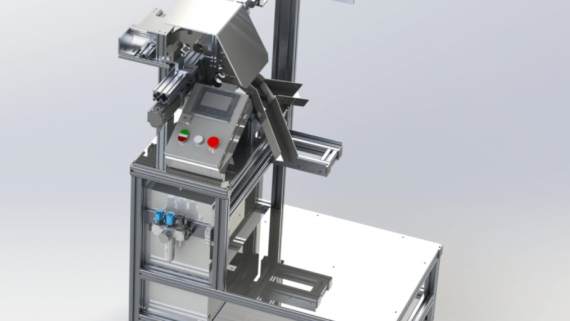

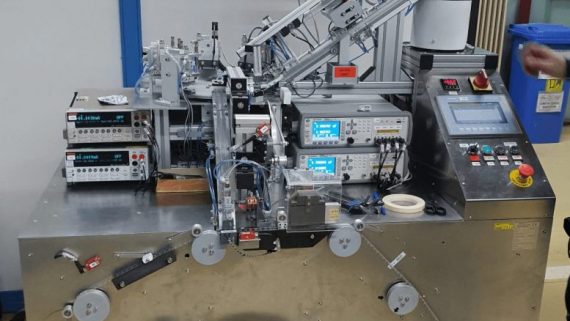

1. Control – Machine control is done with PLC, adequate application software and additional module that controls all controlling, regulation and executive parts of the machine. HMI panel and buttons allows machine control.

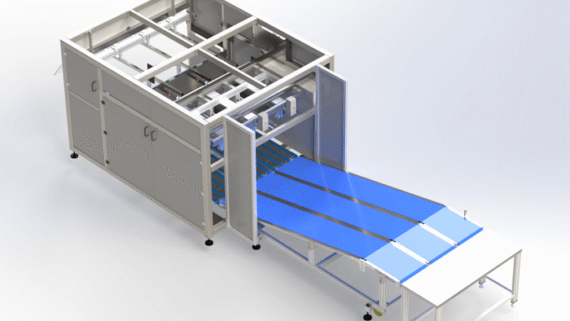

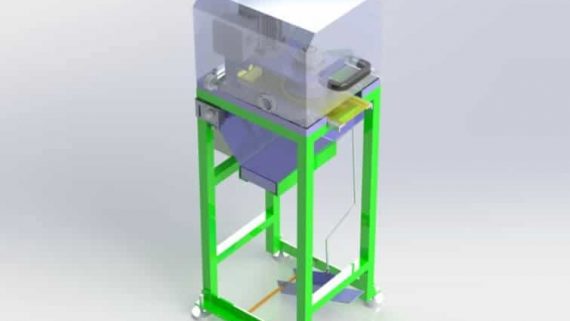

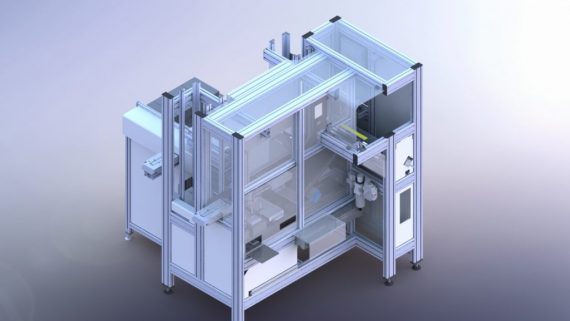

2. Input – Bowl feeder is filled up with plastic parts. From the bowl feeder coming out correct oriented parts to the linear feeder. At the end of the linear feeder there is a stopper that stops the serie of parts.

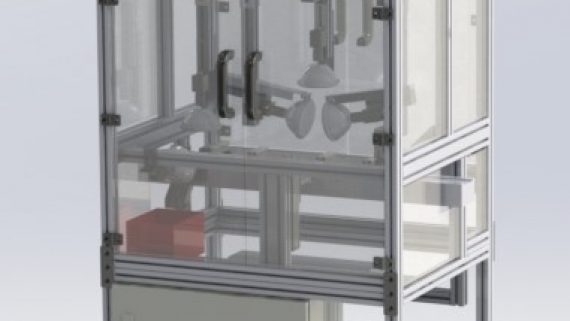

3. Optical control – The part comes to the first station where the upper surface is processed. The rotary cylinder switches to a rotary table where the following three surfaces are processed. After that, the rotary table rotates and the remaining two surfaces are processed.

4. Air blowing system – The PLC turn on an exhaust system depending on the results of the optical control. A blower for OK or NOK parts turns on. Counting the parts in boxes is done.

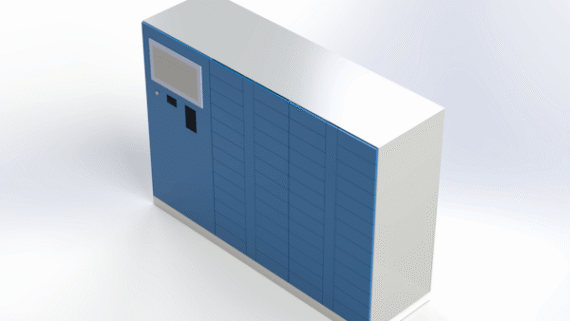

5. Output – At the front of the machine there is space for three boxes. The machine automatically changes boxes when one cycle is complete.

The work of other machines can be seen on our youtube channel.