PLC programming

Programming and commissioning of machines and automated lines controlled by PLC (Programmable Logic Controller). Many years of experience in programming Siemens PLC (Step7 and TIA Portal), Beckhoff PLC (TwinCAT 3).

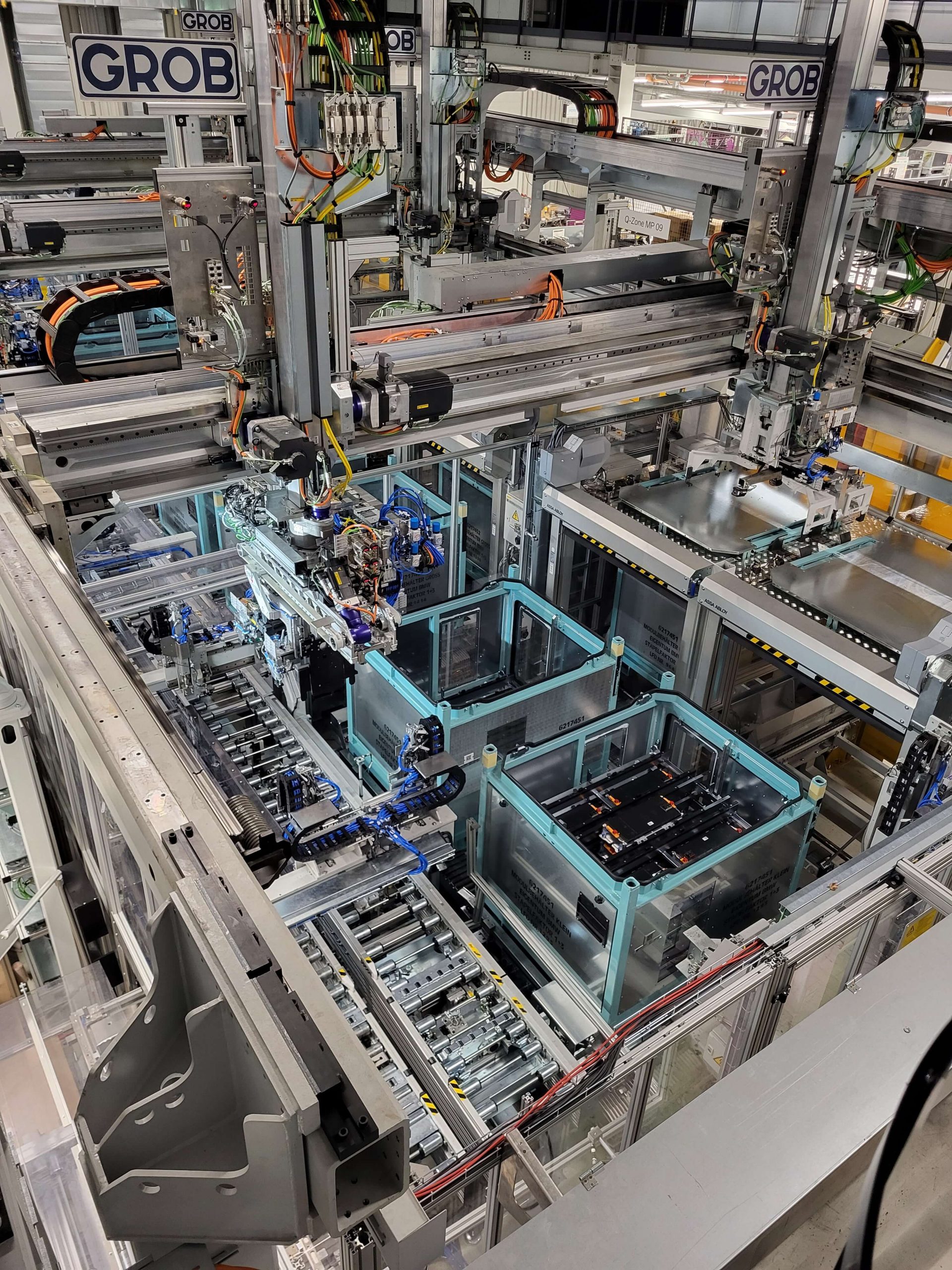

Programming and commissioning of the battery assembly line BMW

PLC programming in the TIA portal.

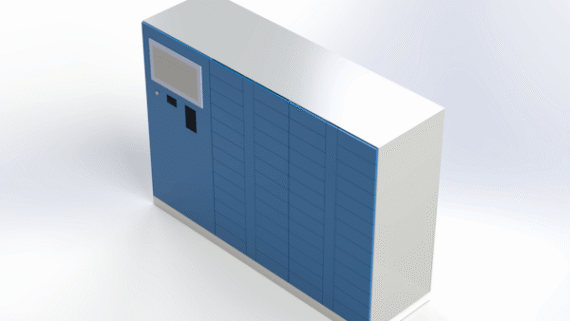

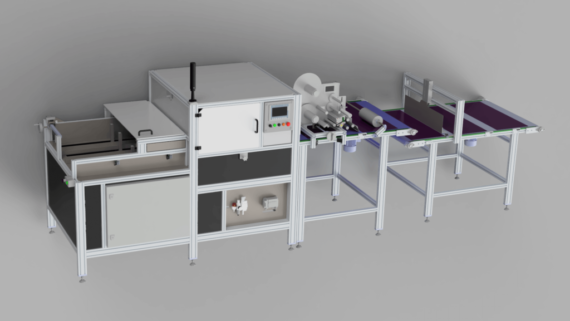

Programming and commissioning of the package transport line

PLC programming on the TIA portal. Line of delivery of empty and shipping of full boxes.

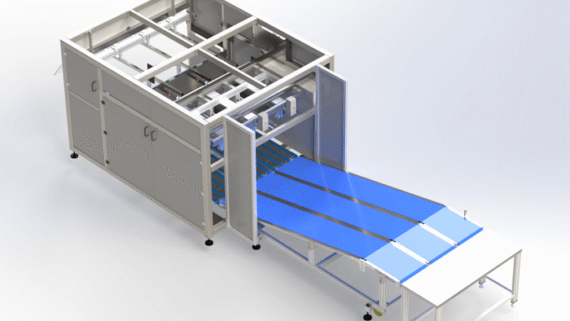

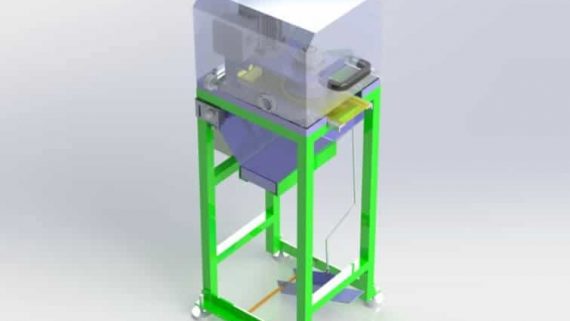

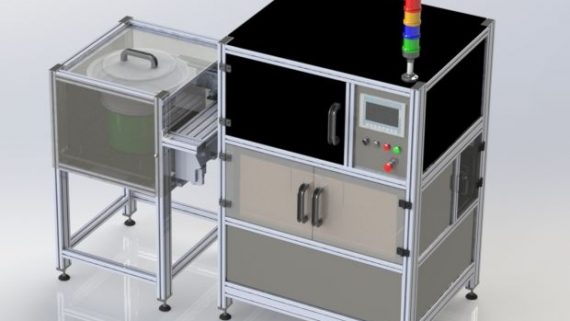

Programming and commissioning of the bottles packing line

PLC programming on the TIA portal. The line consists of 4 segments. The first two entry segments are deplatizers for receiving of empty crates and bottles. Empty crates and bottles are delivered to the next segment that places the bottles in the crates. The last segment is a palletizer that stacks full crates on a pallet.

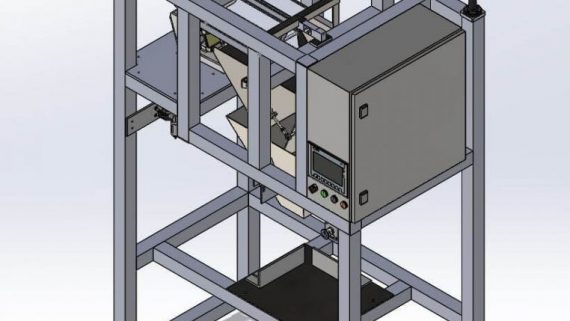

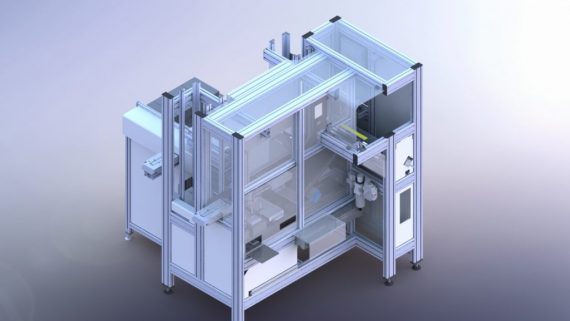

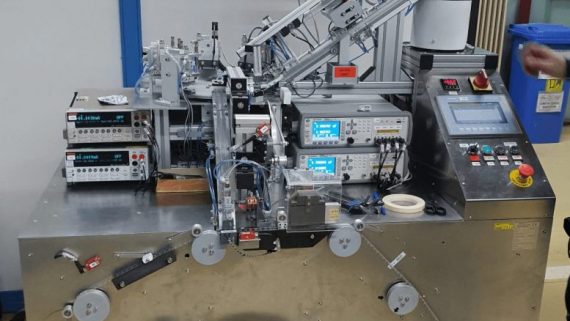

Programming and commissioning of the battery production line

PLC programming on the TIA portal. At the beginning of the line, individual batteries are grouped into various battery packs. In the middle of the process, the batteries are glued, pressed and welded. At the end of the line, electrical measurements are made and battery packs are packed into boxes.

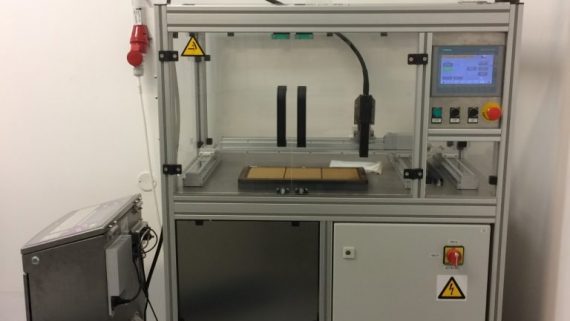

Programming and commissioning of the inverter assembly line for electric vehicles

PLC programming on the TIA portal. The line includes plasma cleaning, screw tightening, optical control, pressing, pick and place and various measurements. The devices on the line are robots, cameras, screw clamping devices, plasma cleaners, gluing units, transport systems, QR code readers, measuring equipment (leakage testing, various electrical tests).

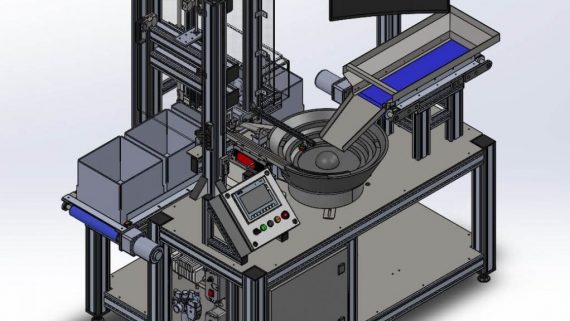

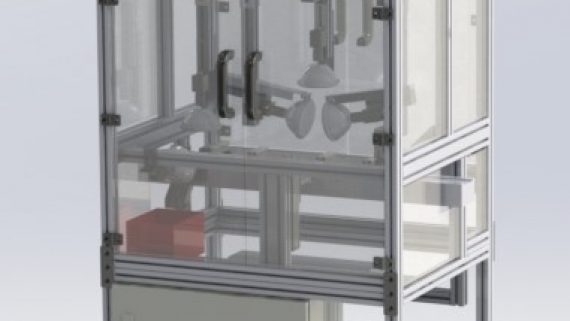

Preparation of programs for PLC, designing and commissioning the machine for assembling the main bracket of a energy regulation switch

The machine is carried out by rotary table and cells for investment, installation, pinning, riveting, welding, checking.

Control is performed by Siemens PLC Series 300 and operating panels for visualization and management.

Turning Table is powered by an electric motor, and the cells are derived by pneumatic manipulators.

All elements of the machine are connected and controlled by PLC (welder, camera). In addition to monitoring data of operations carried out each cell for each nest on the rotary table.

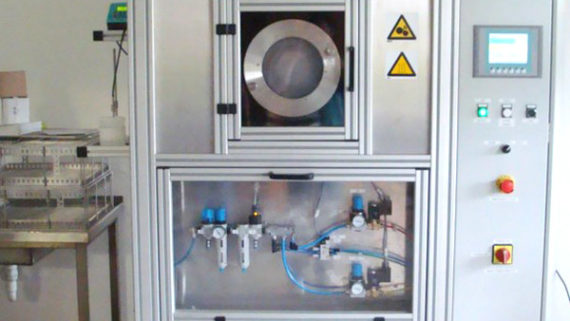

Programming and commissioning of the ovens steel parts for turbine engines

Creating a driver program for Siemens S7-300 PLC – Temperature regulation of oven and other management functions such as records, data storage, management, transport trolley…

Creating user programs for the control panel.

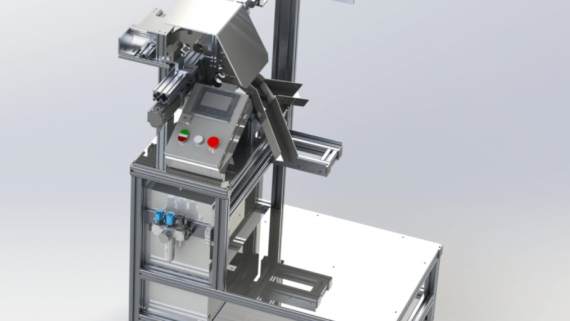

Programming and commissioning of the station for the preparation and installation of the roof body “MINI”

The line is automated with moving rollers to transfer the roof body from cell to cell with movable tables for positioning, and KUKA robots for handling, welding, gluing …

Control is performed Siemens by PLC series 400 and WinCC visualization via computer.

The security part is managed by PLC “PILZ”.

Motors and Drives “SEW” and robots “KUKA” are connected with the PLC via Interbus optical fibres.

Programming and commissioning of the production line for assembling battery for BMW i3 drive

Programming and commissioning of the production line for assembling battery for BMW i3 drive. The line is used for mounting the battery pack, which is installed in the floor of the model I3 and provide power to electric drive.

Management is carried out with more PLCs Siemens S7-300 series and most part of the assembly by robots ABB.

Programming and commissioning line for production carriers of drive shaft for BMW

The line is used for the production of drive shaft. It is automated with Motoman robots and controlled by PLC Siemens 400 series, with visualization “Zenon” over the panel.

Communication via PROFINET provides connection to peripheral input output modules “PILZ”.