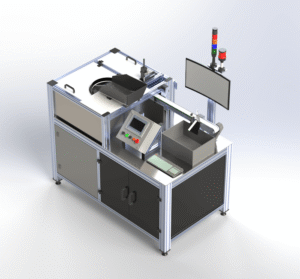

PRIKA is a machine for sorting, marking and transporting of housings.

Actuators: Bowl feeder, linear feeder, pneumatic vibrator, pneumatic cylinders, conveyor belt, printer.

1. Control – The machine is controlled by a PLC. Appropriate software and additional modules are controlling the actuators. Communication between the operator and the machine was performed using HMI panels, pushbuttons and SCADA system.

2. Input – The machine has a tank for unmarked parts of housing. The parts from the tank are dosed into the vibrating feeder.

3. Supply system – The vibrating feeder orients and supplies the pieces to the conveyor belt.

4. Part marking system – The parts come on a conveyor belt where they are additionally positioned using cylinders. The positioned parts come under the head of the printer that prints the appropriate label on the part.

5. Output – The marked parts are transported by conveyor belt further to the box for finished parts where they go for further processing.