See an excerpt of our larger deliveries:

PLC programming in TIA Portal.

Design and construction of a machine for stacking insulation

Designing and manufacturing of a semi-automatic contact soldering machine.

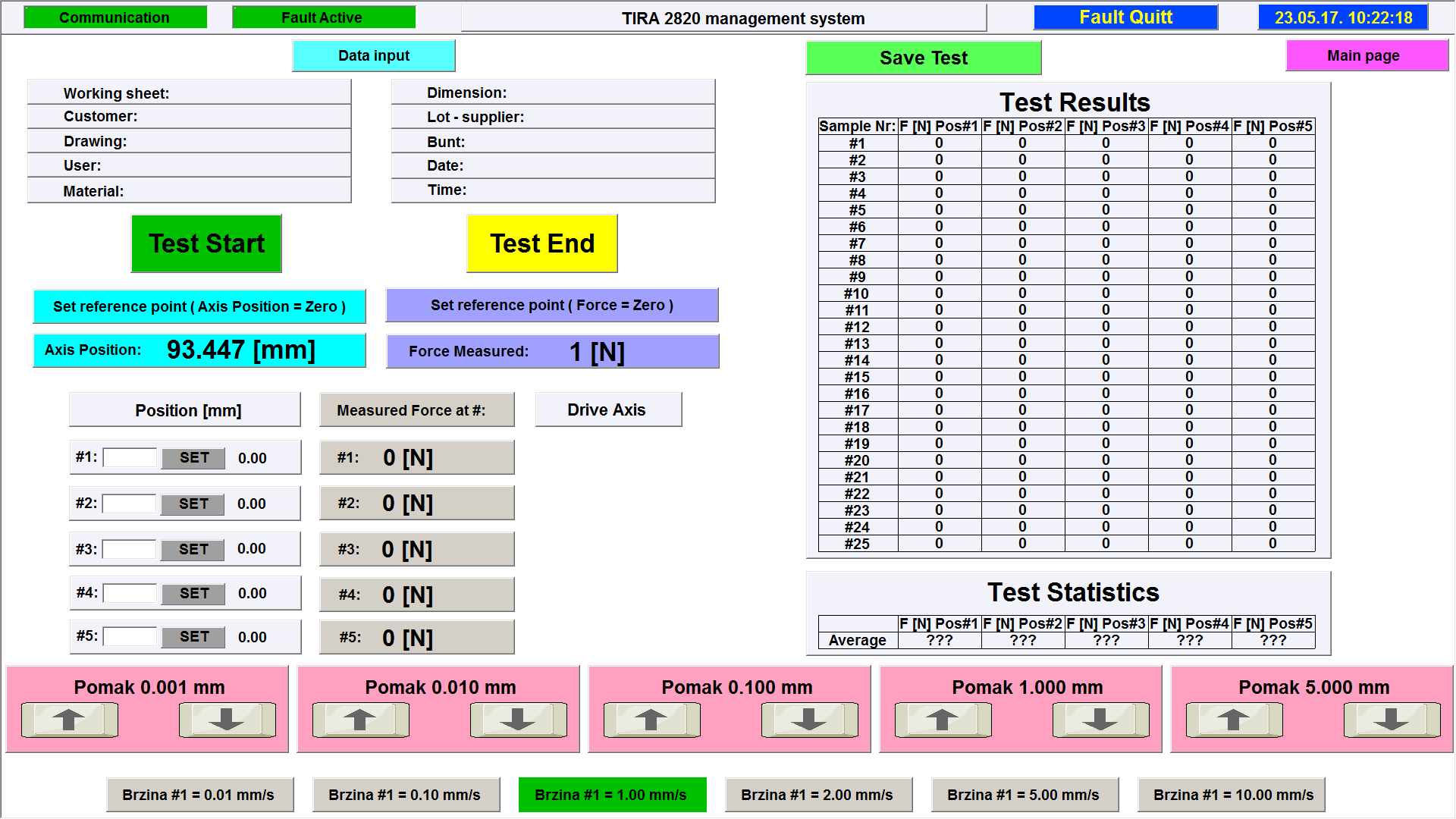

On the existing sheet metal bending machine, a completely new management system was installed with the possibility of writing program recipes and saving them on the server. Additional positioning of the motor according to the data from the recipe is possible.

Implemented with S7 1200 PLC series.

Designing and manufacturing of a machine for testing solderability by immersion.

Design and manufacturing a feeder system.

Link on a feeder system with conveyor

Design and manufacturing a declaration labeling machine.

PLC programming.

PLC programming.

Line retrofit and complete new control with Siemens S7.

Design and manufacturing a machine for feeding individual springs and separating them with balls.

Link on a machine

The fourth delivered GLUSTA machine.

PLC programming.

Production of vibratory feeders for metal parts.

Production of linear vibro feeders for stator and rotor parts.

Design and manufacture of bowl feeder for copper parts.

VIBAK

• Design and construction of the machine (bowl feeder, linear feeder)

• Design and manufacture of electricity

• PLC programming

• Programming of the AOI program

• Creating a visualization

Look the machine video.

Design and manufacture of bowl feeder for needles VIGLO.

Video

Production of a circular feeder for dosing glass fibers into concrete VISTAV.

Video

• Design and construction of the machine

• Design and manufacture of electricity

• PLC programming

• Creating a visualization

Look the machine video.

Design and manufacture of feeding system for rubber parts VIGUP.

Video

Design and manufacturing of feeder for metal parts VIPO.

Video

3D print of a modular model of a tanker for laboratory tests at FSB

BRUS:

• Design and construction of the machine

• Design and manufacture of electricity

Watch machine video here.

PRIKA:

• Design and construction of the machine

• Design and manufacture of electricity

• Design and manufacture of vibratory feeder systems

• PLC programming

• Creating a visualization

Watch machine video here.

AOI Sklopka:

• Design and construction of the machine

• Design and manufacture of electricity

• PLC programming

• Creating a visualization

Watch machine video here.

KRIVULJA:

• Design and construction of the machine

• Design and manufacture of electricity

• PLC programming

• Creating a visualization

Watch machine video here.

Manufacture of EPlan according to Daimler standard

Development of feeder system with pneumatic drive

KOTRA:

• Design and construction of the machine

• Design and manufacture of electricity

• PLC programming

• Development of visualization and SCADA systems

Watch machine video here.

Design and manufacture of electricity for upgrading the forklift with an autonomous guided system

PLC programming in TIA Portal. The line includes plasma cleaning, gluing, screwing, optical inspection, pressing, pick and place and various measurement. The devices are robots, cameras, screwers, plasma cleaner, gluing unit, conveyor system, QR code readers, measurment equipment (leakage test, various electrical test).

Design and manufacture of the bowl and linear feeder consist:

- Design and producing of the bowl for the vibro feeder

- Design and producing of the guide of the linear vibro feeder

- 3D print of the bowl

Design and manufacture of the PLOK machine for optical control and packing plastic components consist:

- Design and producing of the machine construction

- Design and producing bowl and linear feeder

- PLC programming

- Visualization

-

More about machine PLOK.

Design and manufacture of the TUMIX mixing machine consist:

- Design and producing of the machine construction

- PLC programming

- Visualization (SCADA)

- Parameterization of the vertical and circular mixer motor drives

More about machine TUMIX.

Design and manufacture of the PREMKO rewinding machine consist:

- Design and producing of the machine construction

- PLC programming

- Visualization

- Parameter of the winder and rewinder drive

More about machine PREMKO.

Design and manufacture of the GLUSTA machine for gluing consist:

- Desing and producing machine construction

- PLC programming

- Visualization

- Parameterization of conveyor drive and linear slider drives

More about machine GLUSTA.

Design and manufacture of the KOMPA machine for control and packing electronic components consist:

- Design and producing of the machine construction

- PLC programming

- Development of the optical check software

- Production of the bowl feeder

- Visualization

- Parameterization of the carrier tape servo drive for component packaging

More about machine KOMPA.

Design and manufacture of the BRIZ electronic component packaging machine consist:

- Design and manufacture of the machine construction

- PLC programming

- Optical counting software development

- Visualization (SCADA)

-

More about machine BRIZ.

Design and manufacture of the EPRI electronic component packaging machine consist:

- Design and manufacture of the machine construction

- PLC programming

- Visualization

-

More about machine EPRI.

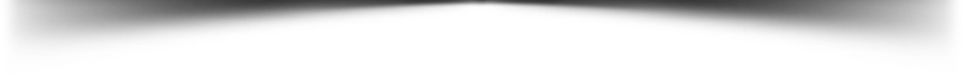

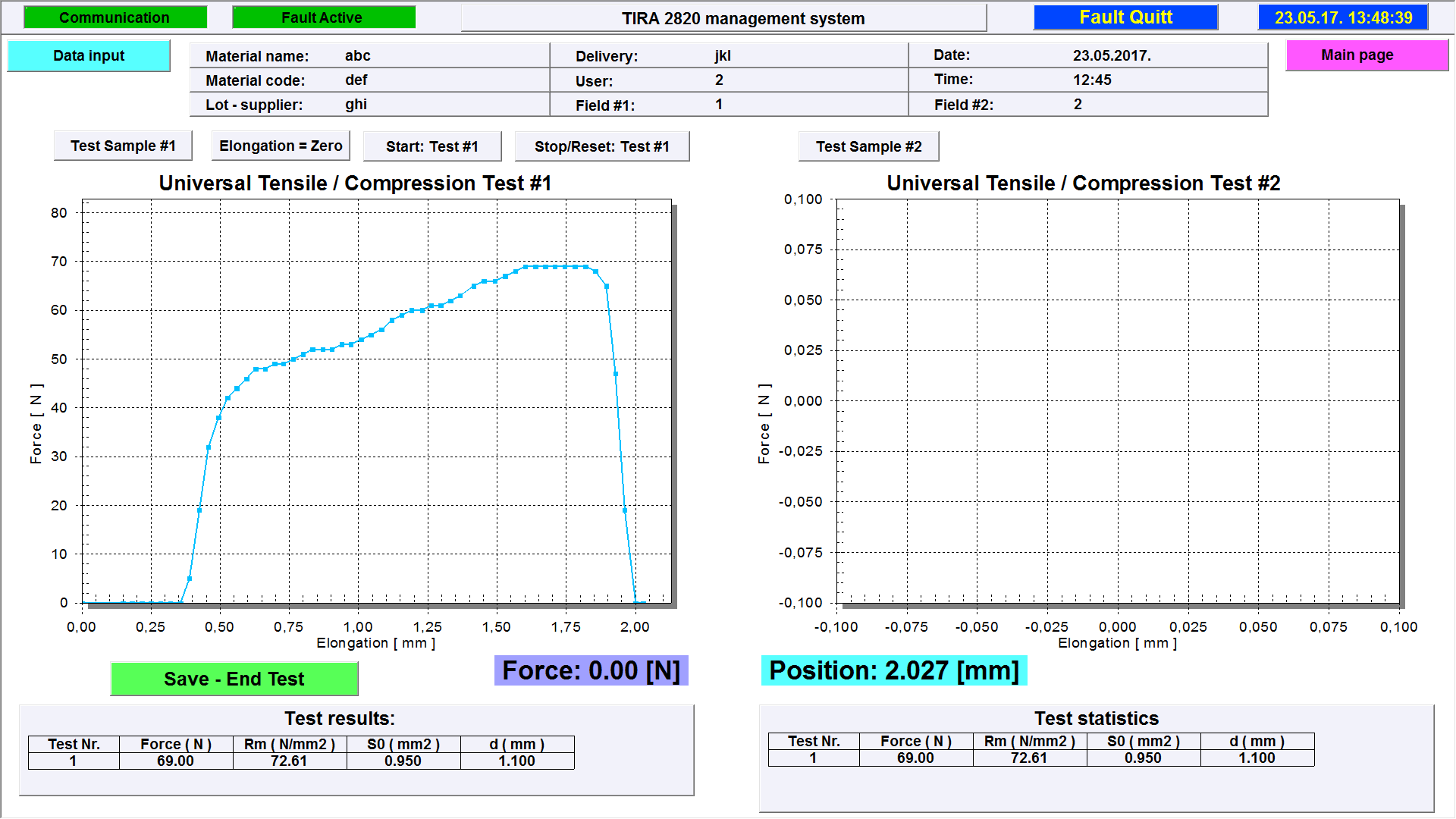

Reconstruction of machine was implemented in 3 parts:

- Proces visualization (SCADA) for easy access of parameters (Force, position) and data display on graph

- PLC programming

- Servo motor and mechanics upgrade

Programming and commissioning of the proces of cutting carbon parts for i-series of electric cars (BMW, Landshut) 2017.god.

Programming and commissioning of the production line for the hood of the Jaguar in Allbersdorf.

Programming and commissioning the machine for hydro design – making expansion joins.

Electrical design and manufacture of EPLAN for the BMW Landshut, project 3D Printing parts.

Programming and visualization of final asembly for BMW South Africa .

Reconstruction, repair and upgrade of an elasticity meter for spring quality control.

Programming and commissioning the machine for installation of energetic switches (Elektro kontakt, Zagreb) 2014.

Commissioning stations for PVC filling for AUDI body (AUDI, Ingolstadt) 2014.

Programming and commissioning of the stations for PVC filling for AUDI body (AUDI, Ingolstadt) 2014.

Upgrading control, flow, temperature, humiditiy, and data on the machine “LAKI” (SELK, Kutina) 2014.

Design and manufacture of machine for cleaning giters (SELK, Kutina) 2014.