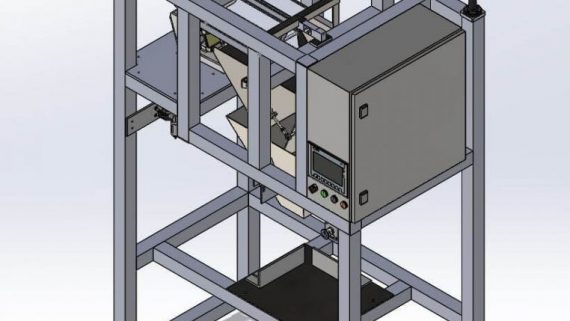

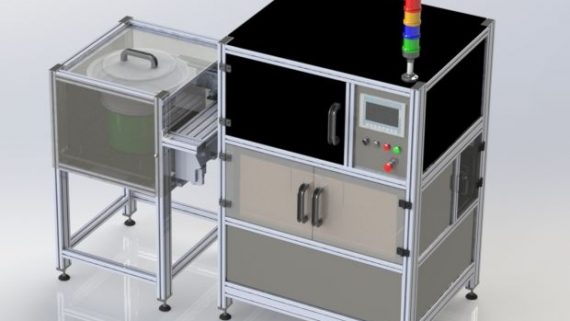

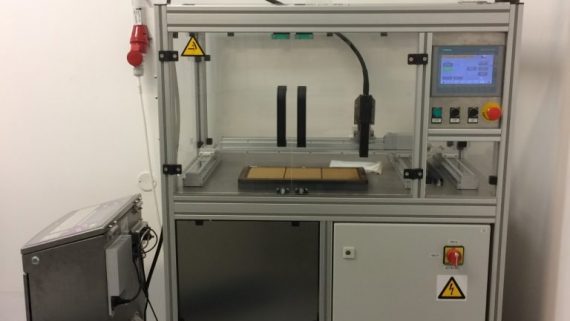

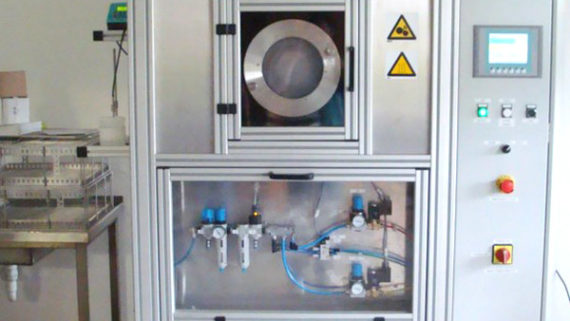

MARA – Machine for magnetic separation

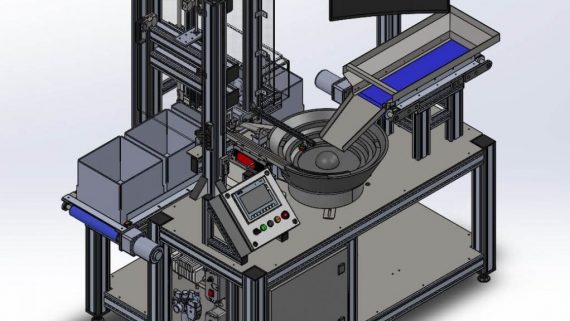

Basic description

After galvanizing procedure, pieces are receiving layer of material with magnetic properties. The function of MARA is the separation of magnetic (galvanized) from non-magnetic (not enough or not galvanized) pieces and sorting them into related containers.

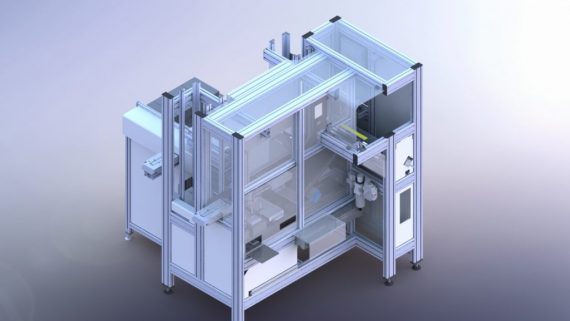

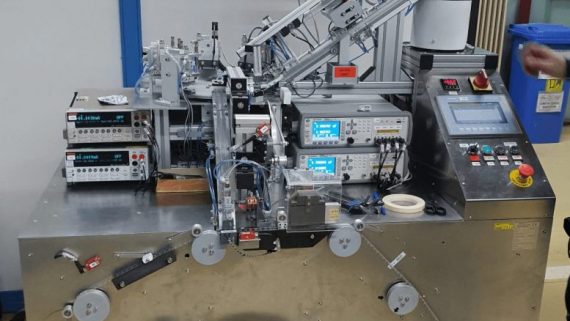

Work principles

Magnetic material collects on the metal sheet under influence of primary magnet. In specified position, primary magnet, under influence of second magnet, moves back on its guides. Material falls of sheet metal because backed primary magnet doesn’t have enough force to hold it.

Magnetic separation process

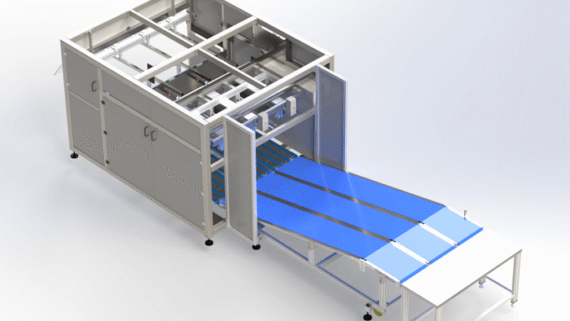

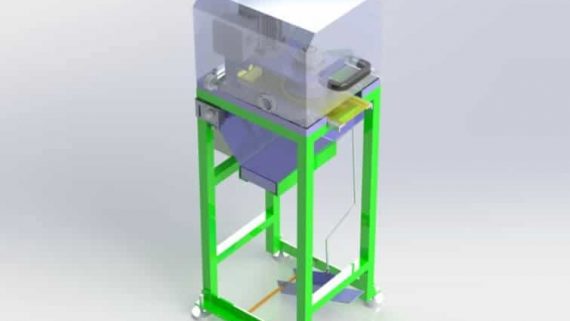

1. Machine loading

Unsorted material is loaded in input funnel. Material moves and distributes in one layer on plate under influence of pneumatic vibrator.

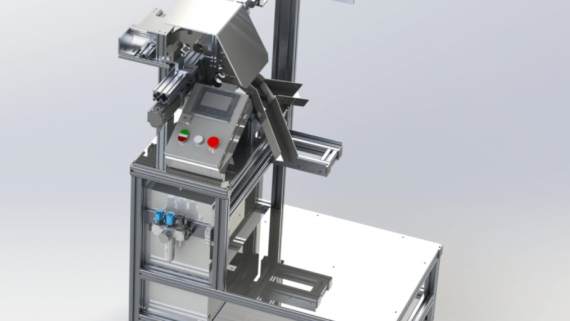

2. Transport plate loading and material distribution

Pneumatic vibrator moves and distributes material in one layer on transport plate

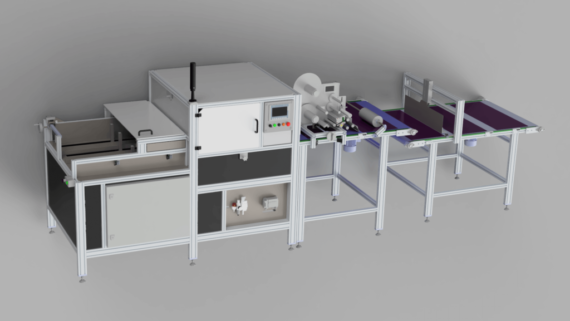

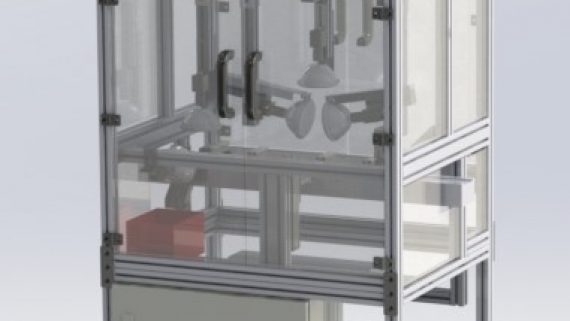

3. Separation

Rotor with moving primary magnets collects magnetic material on rotor surface.

During rotation, in specified position, under influence of secondary magnet primary magnet moves back and unloads material from its surface.

4. Machine unloading

Nonmagnetic material moves under rotor and falls into output container for nonmagnetic material.

Magnetic material, unloaded of rotor, falls into output channel and slides to magnetic material container.

Document with pictures and magnetic separation process is avalaible here.

Video of working machine is avalaible on our youtube channel : MARA