LAKI - Machine for electronic component passivation

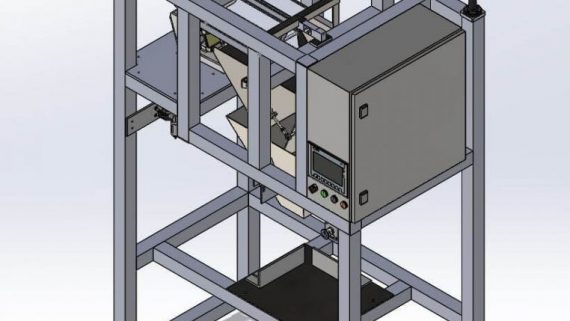

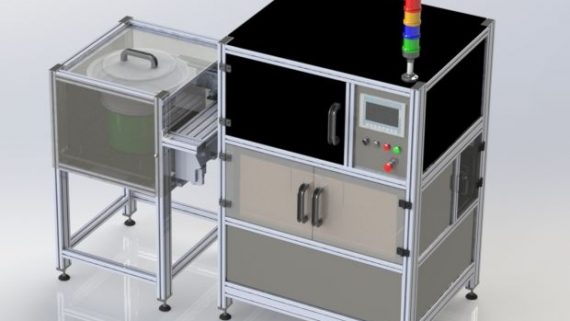

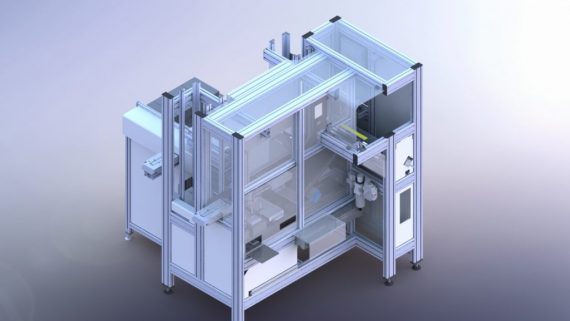

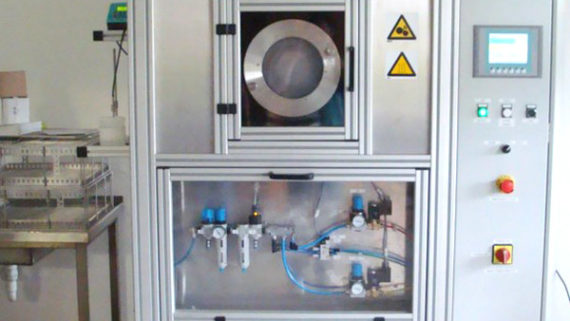

Designing and manufacture of the machine for the passivation of electronic components – automated machine

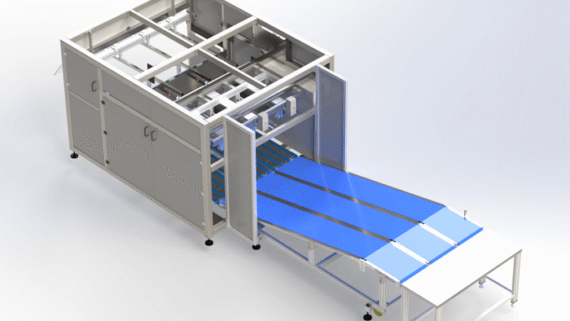

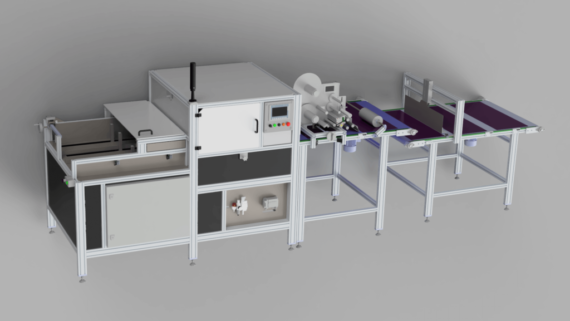

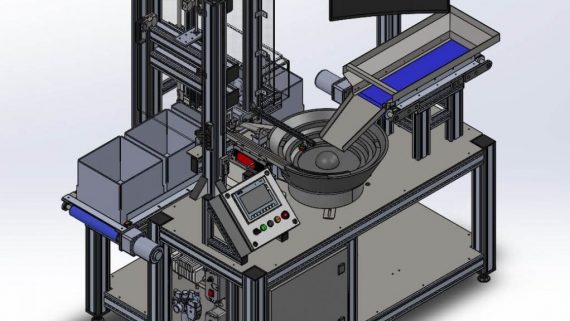

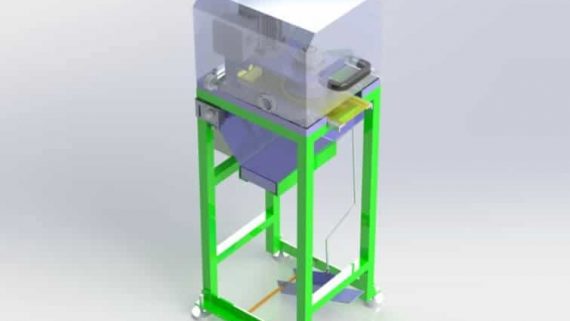

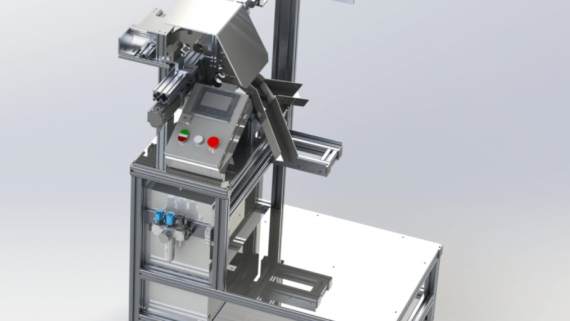

The machine is designed for passivation electronics components. It consists of a drum that spins, preparation of air, spraying liquid for passivation and output filter.

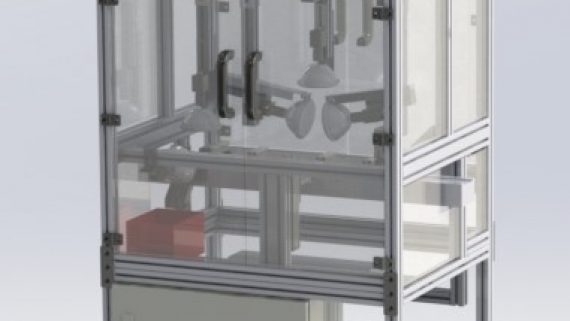

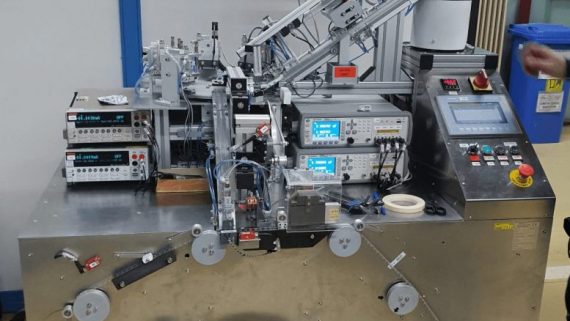

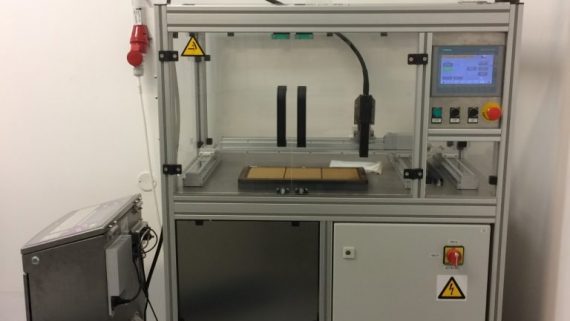

The first sequence of the machine is preheating, during which warm air is blown through the heating and blowing system while drum simultaneously spins turning the production pieces around. By reaching target temperature and maintaining the same for a specified time automatically starts passivation sequence.

The second sequence is lacquering which consists of a periodic spraying of lacquer in the spray form, blowing air of constant temperature and flow and turning the pieces by drum spinning. The selected program parameters are setting requirements for speed, temperature, number and duration of spraying.

The third sequence is pieces drying by blowing air of constant temperature and flow, with simultaneous spinning the drum. After time out, drying machine automatically ejects done pieces and waits for the operator to open the door and put a funnel for emptying. By pressing the “Start” button sequence for emptying is started.

The fourth sequence is emptying pieces. The drum spins in the opposite direction (clockwise rotation), and production pieces are discharged in a channel which leads in the container.

Document with pictures and passivation procces are available here.