KOMPA is a machine for orienting, optical and electrical measuring and packaging of electronic components. The final product is full carrier tape with sorted and processed electronic components.

1. Control – Operations are performed automatically by the PLC controlling program. Actuators are servo drives and pneumatic cylinders.

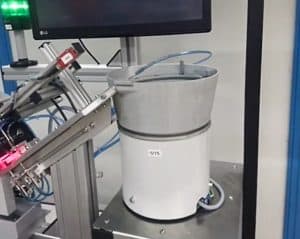

2. Infeed section – Operator puts parts in bowl feeder. At the outlet of the bowl feeder the parts are oriented properly.

3. Optical measurement system – Components come on the optical control with camera to measure the dimensions of the parts

4. Electrical measurement system – Optically good components come on the rotary table for electrical measurement.

5. Marking system – Electrically good components are marked.

6. Filling the carrier tape – Marked parts fill the carrier tape. Tape is moves depending on the number of parts in the nest on the table. Heater welds the cover the carrier tape.