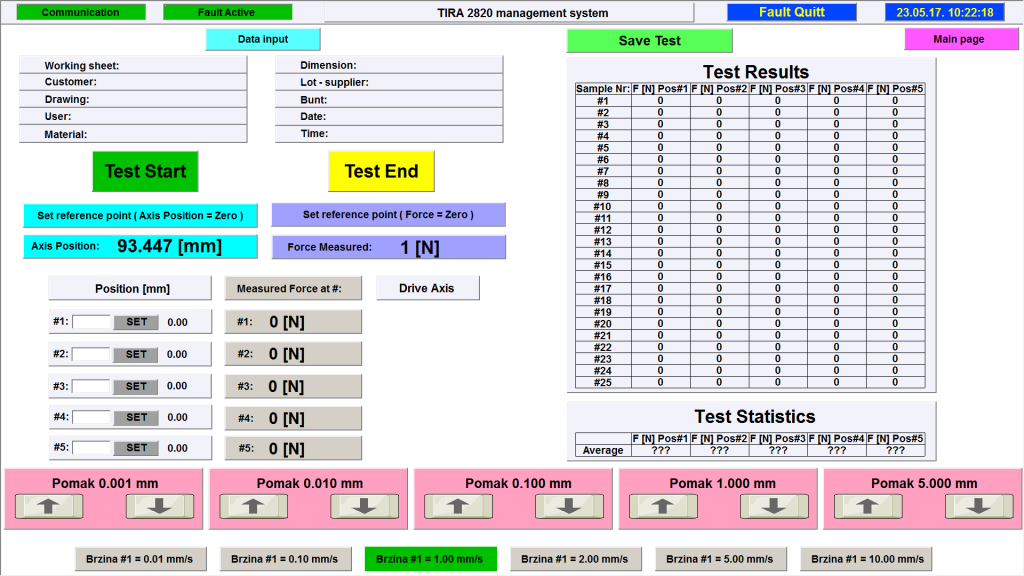

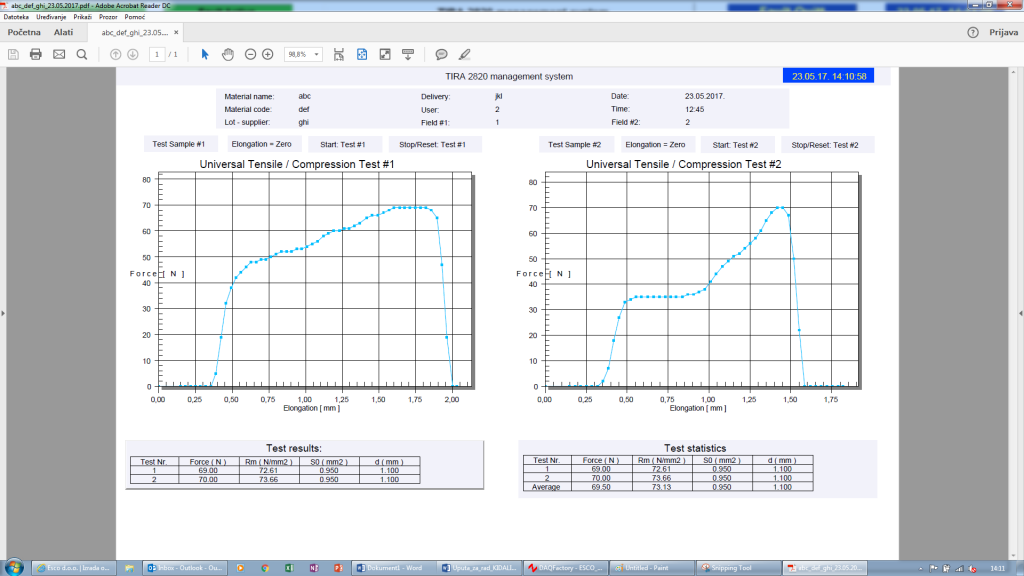

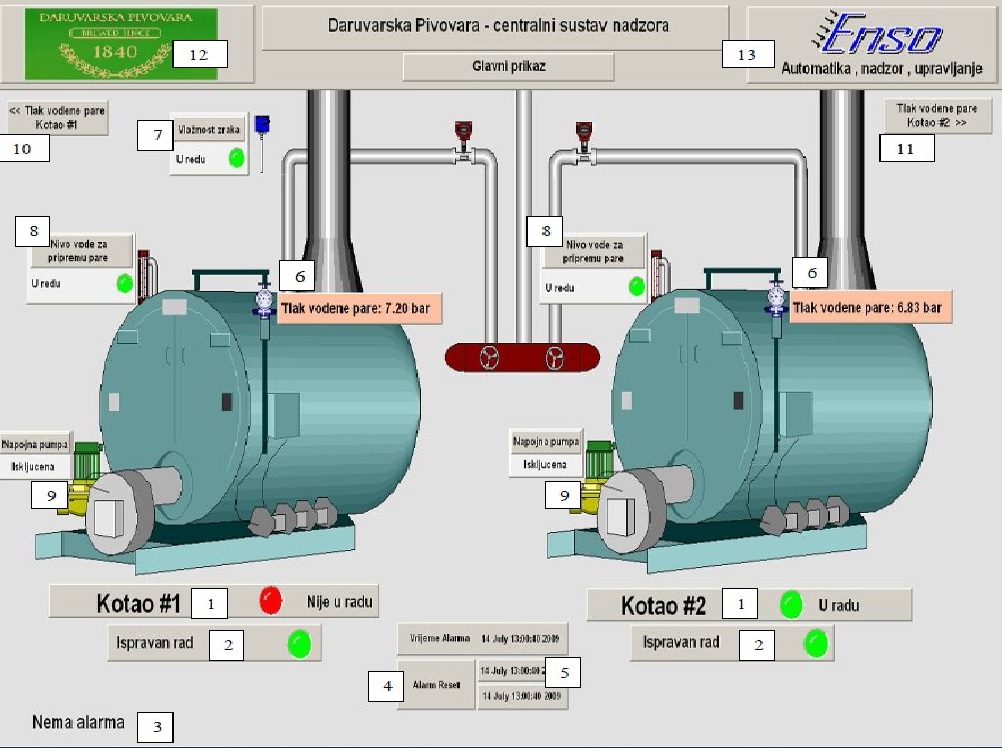

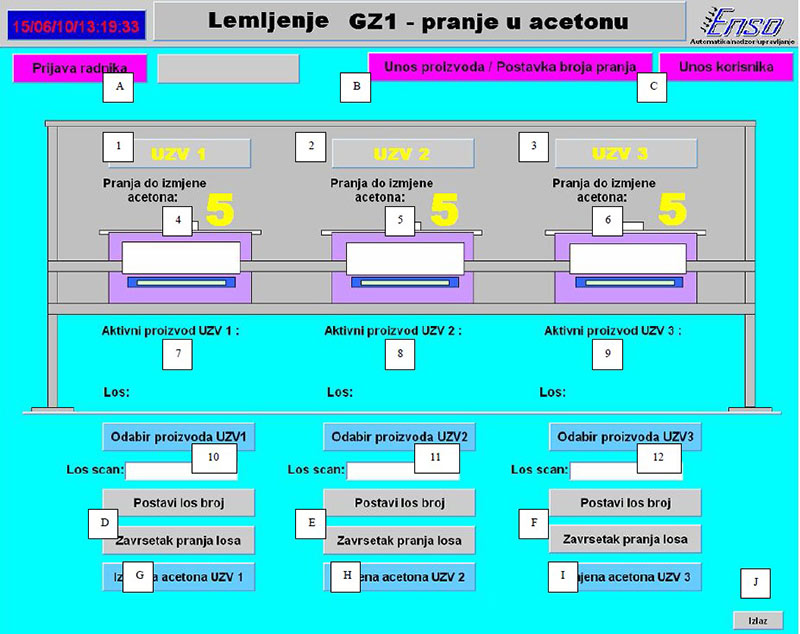

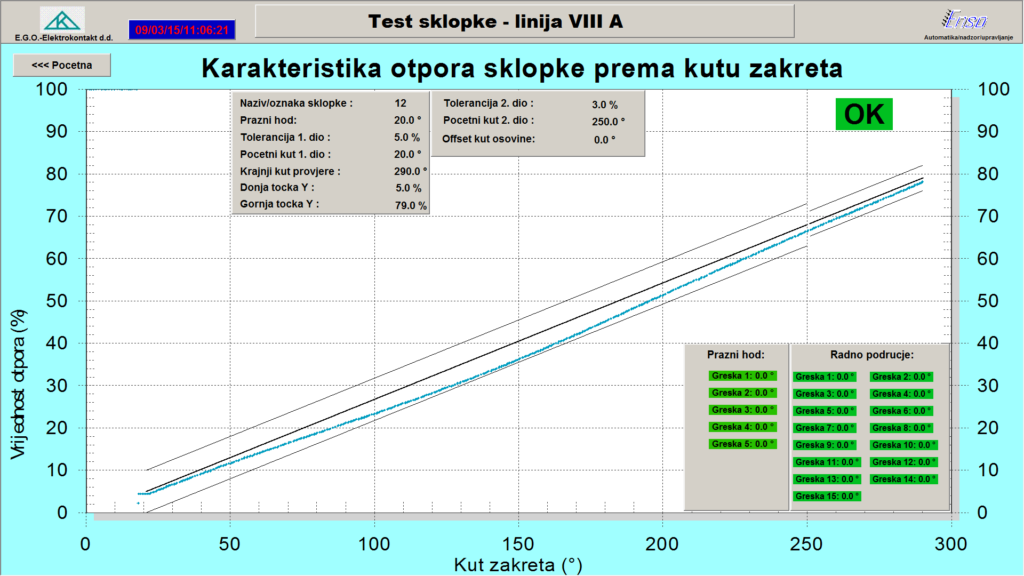

Design of modern web applications for processing and displaying data collected on the production line or machines. Design of databases and their export to desired files.

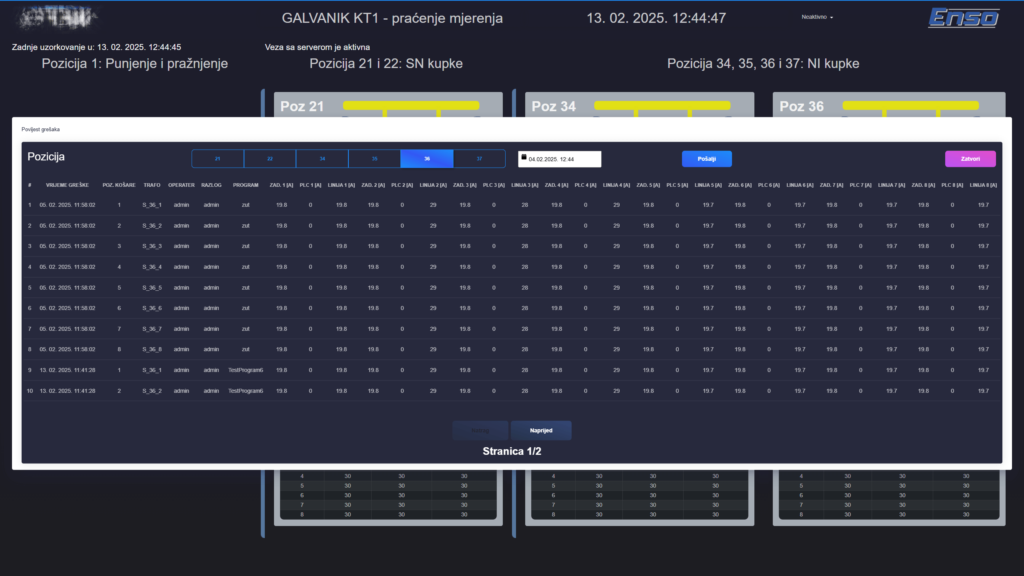

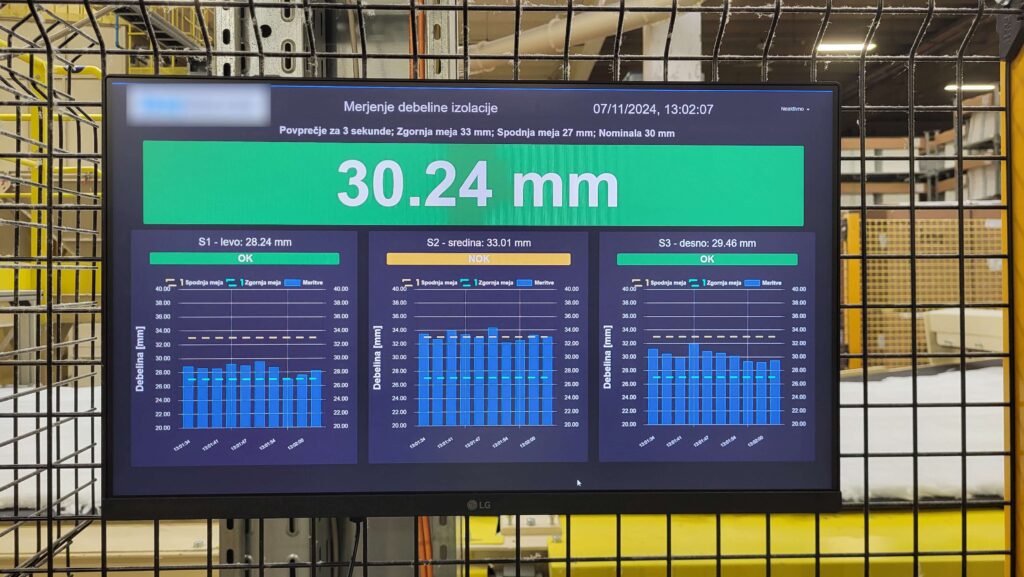

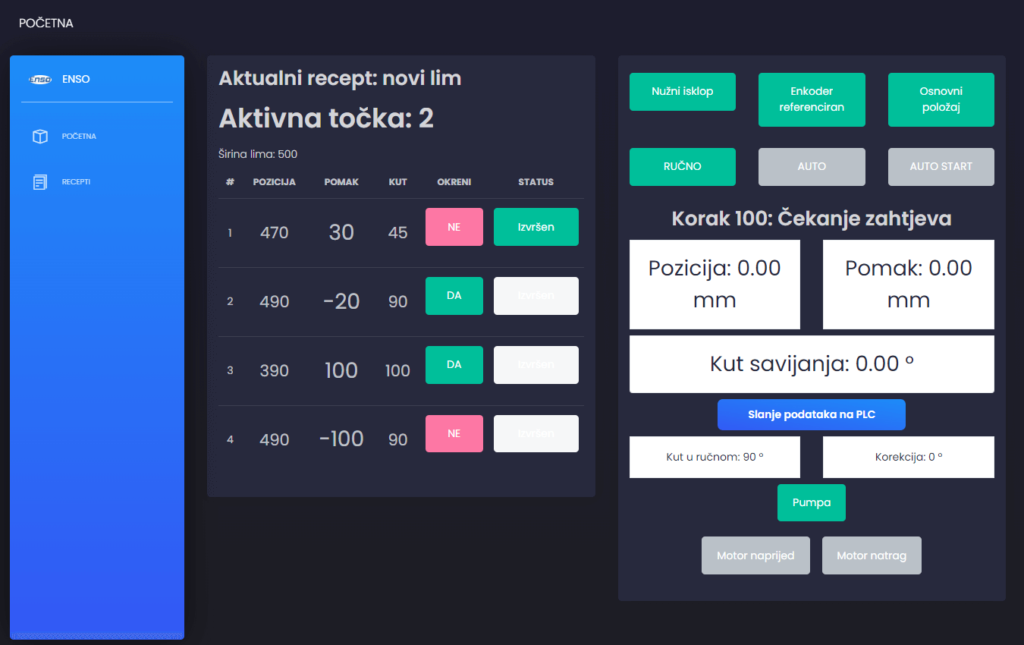

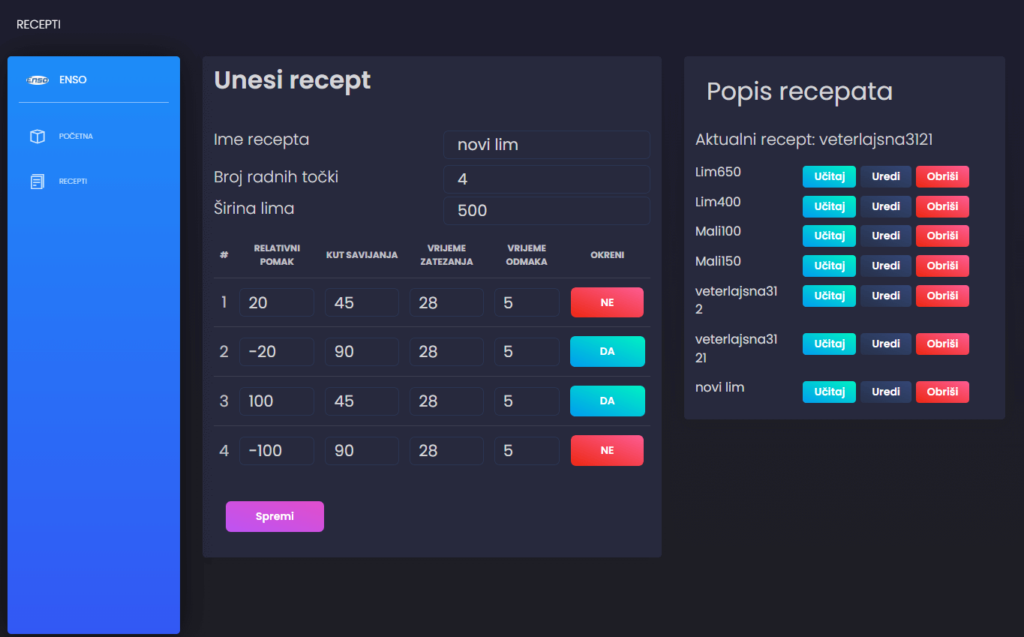

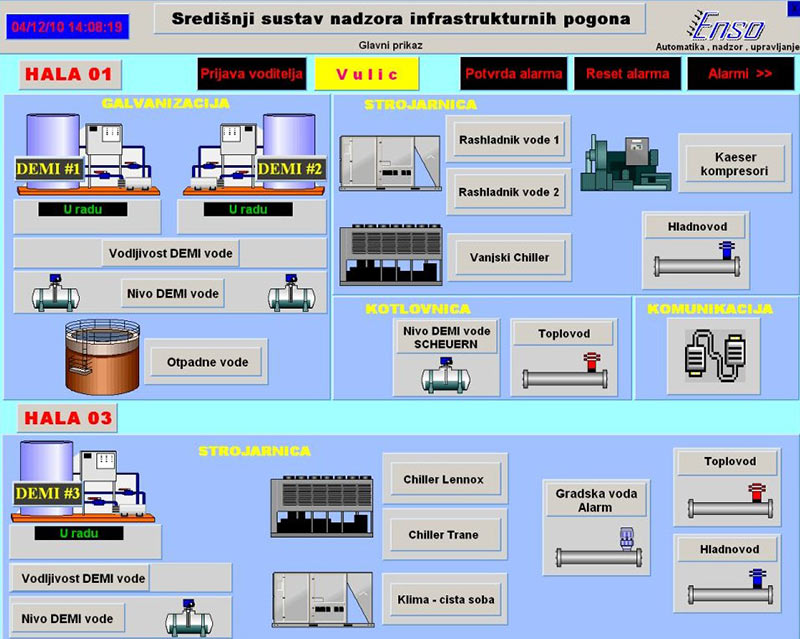

Our SCADA apps, which collect data from PLCs and process it on local servers, are a natural part of the IoT (Internet of Things) paradigm. By connecting sensors, actuators, and other devices to a central application, we enable real-time data collection, visualization, and analysis. Using web technologies, the same data and system monitoring are available on any device – from desktop computers to tablets and smartphones – without the need for additional installations. This approach allows simultaneous access and management from multiple locations, optimizing production processes, enabling predictive maintenance, and supporting faster, data-driven decisions. The combination of IoT and web platforms ensures maximum flexibility, transparency, and efficiency in managing production systems.

Frontend: HTML, CSS, JavaScript, React

Backend: ASP.NET Core (Web API, NVC), C#, MS SQL, My SQL

- graph generation

- user login/logout

- CRUD for operator list, errors

- settings

- table view of error histor

- error reporting