3D print

The 3D printing is computer-controlled process of forming a three-dimensional object by material merging. One method of making prototypes or functional objects is called material extrusion. The most commonly used material extrusion technology is fused deposition modeling (FDM). The low-melting thermoplastic (3D filament) is fed to an extruder where it is melted and applied to a work surface where it is immediately solidified.

This method significantly reduces the amount of material required to make the prototype and makes easier to produce more variants of the prototype for testing.

The 3D printer consists of a 3D positioning system. 3D positioning is done using the drive for each axis. Adjusting the settings and tracking the print status can be done on the printer panel. The SD card contains the G code file generated from the computer where the print commands are. The heater is located on the extruder and on the build plate. Different types of 3D filaments require different heater temperature settings. There is a filament nozzle on the extruder to apply filament. The 3D filament is wound up in a collet. The filament is melted in the extruder so that it can be applied on the build plate. The new layer is printed on the existing one.

3D printing benefits:

Easy prototyping for testing various applications.

Availability of the prototype itself depending on the complexity of the object / model itself.

Repeatability – Repeat printing is simple and as such does not require a different machine acceptance or tool change.

Price – much less than the standard production process on CNC machines.

3D print disadvantages:

Limited material range.

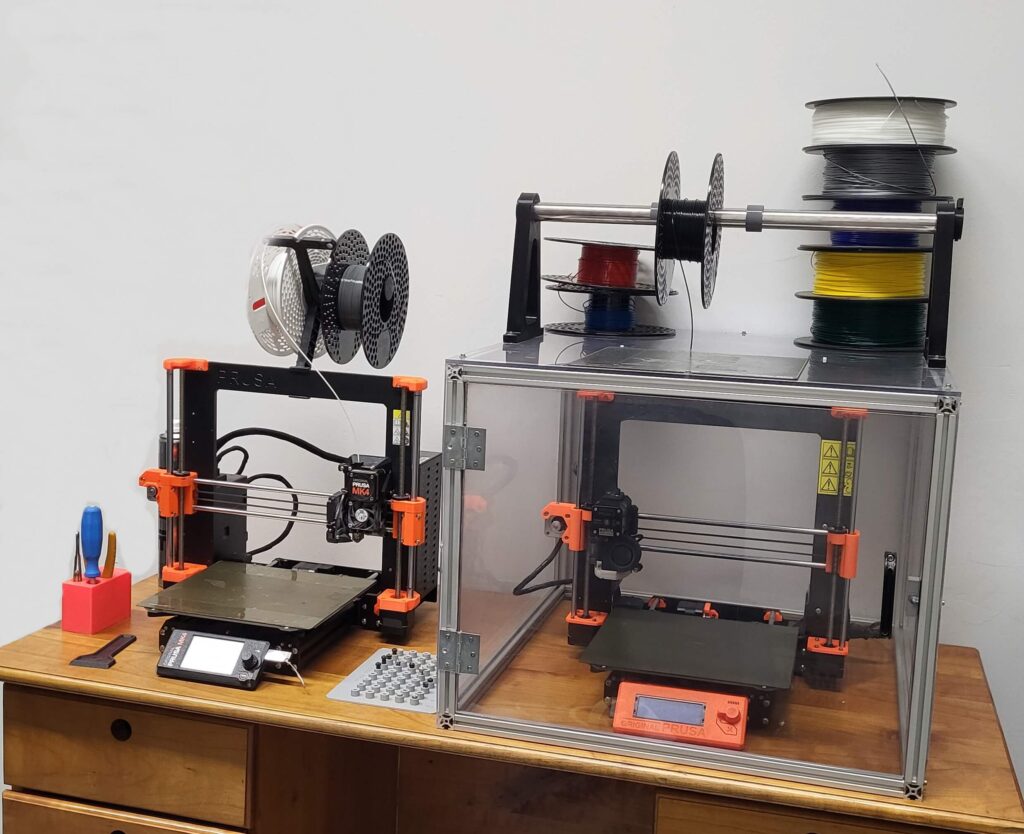

We own 2 printers for small dimensions and 3 for large ones.

The maximum print dimensions are 600x600x600 mm.

3D printed tanker for tests in the college laboratory